Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Have you ever wondered why your food spoils quickly? Sealer machines like vacuum and heat sealers might be the solution. These devices play a crucial role in food preservation by creating airtight seals to protect contents from spoilage. In this article, you'll learn about the differences between vacuum sealers and heat sealers, and how to choose the right one for your needs. We'll explore their functions, benefits, and applications, including portable sealer options and step-by-step heat sealer usage.

A vacuum sealer is a device designed to remove air from packaging, creating a tight seal around the contents. By extracting oxygen, it slows down the growth of bacteria and mold, preserving food freshness longer than traditional storage methods. The machine works by placing food inside a special plastic bag, then pulling out the air before sealing the bag shut using heat. This process not only protects food from spoilage but also prevents freezer burn and dehydration.

Vacuum sealers are widely used in households and commercial settings alike. They help keep food fresh, maintain flavor, and reduce waste. The sealed environment extends shelf life, making it ideal for meats, vegetables, cheeses, and even non-food items like documents or electronics.

Vacuum sealers come in several types, each suited for different needs:

External Vacuum Sealers: These are common for home use. The open end of the bag is placed inside the machine, which removes air and seals it. They’re compact, easy to use, and affordable.

Chamber Vacuum Sealers: These machines are more advanced and used in commercial kitchens. The entire bag goes inside a chamber where air is removed both inside and outside the bag before sealing. This method works better for liquids and delicate foods.

Handheld Vacuum Sealers: Portable and convenient, these devices are perfect for quick sealing jobs or travel. They usually work with special bags or containers but may not remove as much air as larger models.

Vacuum Seal Containers: Not machines, but containers designed to be vacuum-sealed using a pump or vacuum sealer accessory. Great for storing foods that don’t work well in bags.

Vacuum sealers offer several advantages that make them popular:

Extended Shelf Life: Removing air slows spoilage, keeping food fresh weeks or months longer.

Preservation of Nutrients and Flavor: Vacuum sealing locks in moisture, vitamins, and taste.

Space Saving: Vacuum-sealed bags take up less room in the fridge or freezer.

Cost Efficiency: Buying food in bulk and sealing it saves money over time.

Reduction of Food Waste: By preserving leftovers and perishable items, less food ends up in the trash.

Protection from Freezer Burn: Air exposure causes freezer burn, which vacuum sealing prevents.

Versatility: Can seal a variety of foods, including raw, cooked, and dry goods.

For example, sealing fresh berries immediately after picking can keep them firm and flavorful for weeks longer than storing them in a regular container (example data, verify for accuracy).

In sum, vacuum sealers provide an effective way to maintain food quality, reduce waste, and save money. They are a valuable tool for anyone looking to improve food storage and preservation.

A heat sealer is a device that uses heat to fuse plastic materials together, creating an airtight and secure seal. Unlike vacuum sealers, heat sealers do not remove air from the packaging; instead, they melt the edges of plastic bags or films, bonding them tightly to protect contents from external elements such as moisture, dust, and contaminants.

The basic operation involves placing the open end of a plastic bag between heated sealing bars or plates. When activated, the heat melts the plastic's surface, and pressure presses the layers together. Once cooled, the plastic hardens, forming a strong seal. This process is quick and effective, commonly used for packaging food, medical supplies, electronics, and other products needing protection.

Heat sealers come in various designs, from simple handheld devices to large, automated machines used in factories. They work best with thermoplastic materials like polyethylene (PE) and polypropylene (PP), which respond well to heat fusion.

Several types of heat sealers cater to different sealing needs:

Impulse Heat Sealers: These sealers use a brief pulse of electricity to generate heat. The sealing element heats only when activated, making them energy-efficient and safer. They are popular in home kitchens and small businesses.

Constant Heat Sealers: These maintain a continuous heat supply to the sealing element. They allow for faster sealing but consume more energy and require caution to avoid burns. Often used in industrial settings.

Band Sealers: Designed for continuous sealing of bags on a production line. They use a heated band that moves the bag through to create a seal, ideal for high-volume packaging.

Vacuum Heat Sealers: These combine vacuum sealing and heat sealing functions. They remove air before applying heat to seal the bag. While technically a hybrid, they rely on heat to form the seal.

Handheld Heat Sealers: Small, portable devices ideal for quick repairs or small sealing tasks. They often use a heated wire or strip to seal plastic bags.

Heat sealers offer several advantages that make them a popular choice for packaging:

Simple and Fast: The sealing process is quick, usually taking just a few seconds.

Cost-Effective: Heat sealers tend to be less expensive than vacuum sealers, especially for basic models.

Versatile: They can seal a wide range of plastic films and bags, including those not compatible with vacuum sealing.

Effective Barrier: Seals created are strong and protect contents from moisture, dust, and air exposure.

Easy to Use: Most models require minimal training, making them accessible for home and commercial users.

Low Maintenance: Heat sealers have fewer moving parts and are generally easy to clean and maintain.

For example, sealing snack bags or frozen vegetables using a heat sealer helps keep them fresh by preventing moisture and air entry, extending shelf life compared to unsealed packaging (example data, verify for accuracy).

In summary, heat sealers provide a straightforward, reliable way to protect products by creating airtight seals. They serve multiple industries and household needs, offering a practical solution where vacuum sealing may not be necessary or feasible.

Vacuum sealers and heat sealers work differently to protect contents. A vacuum sealer removes air from the bag, creating a near-vacuum environment before sealing it shut with heat. This air removal slows spoilage by limiting oxygen exposure. Heat sealers, on the other hand, don’t remove air. They simply use heated bars or plates to melt and fuse plastic bag edges, creating a tight, airtight seal. The difference lies in vacuum sealers actively extracting air, while heat sealers rely solely on heat and pressure to close the package.

Vacuum sealers excel in food preservation, especially for perishable items like meats, vegetables, and cheeses. They extend shelf life by preventing bacteria growth and freezer burn. Vacuum sealers also work well for marinating food quickly and storing non-food items safely. Commercial kitchens, hunters, and home cooks often use them.

Heat sealers suit situations where air removal isn’t necessary but protection from moisture, dust, or contamination is important. They seal snack bags, medical supplies, electronics packaging, and other products requiring a secure barrier. Heat sealers handle a wider variety of plastics, including those not compatible with vacuum sealing. They are common in industrial packaging lines and small businesses.

Vacuum sealers generally cost more upfront due to their more complex technology. Chamber vacuum sealers, in particular, can be pricey but offer advanced sealing for liquids and delicate foods. External and handheld vacuum sealers are more affordable but still usually cost more than basic heat sealers.

Heat sealers tend to be less expensive and simpler to maintain. They have fewer moving parts and don’t require pumps or vacuum chambers. Regular cleaning of sealing bars and replacing worn sealing elements keeps them working well. Vacuum sealers need more care, including pump maintenance and occasional gasket replacement.

| Feature | Vacuum Sealer | Heat Sealer |

|---|---|---|

| Air Removal | Yes, removes air before sealing | No, seals with heat only |

| Seal Type | Heat + vacuum | Heat only |

| Best For | Long-term food preservation, liquids | Quick sealing, non-perishable items |

| Plastic Compatibility | Special vacuum bags or containers | Wide range of plastic films and bags |

| Cost | Higher, especially commercial models | Lower, especially basic models |

| Maintenance | More complex, pump and gasket care | Simple, clean sealing bars regularly |

Understanding these differences helps choose the right sealer for your needs. Vacuum sealers offer superior preservation by removing air, ideal for food storage. Heat sealers provide fast, cost-effective sealing for many packaging tasks without vacuuming. Both have their place depending on what you want to seal and how long you need it preserved.

Before sealing, gather all materials: the heat sealer, plastic bags or films, and the items to be packaged. Make sure the plastic is compatible with heat sealing — usually polyethylene (PE) or polypropylene (PP). Cut the bag or film to the desired size, leaving enough length for sealing (at least 1 to 2 inches beyond the product).

Clean the sealing bars or plates on the heat sealer. Dust, crumbs, or residue can weaken the seal. Use a soft cloth slightly dampened with water or rubbing alcohol to wipe the surfaces. Ensure the heat sealer is on a flat, stable surface and plugged in if electric.

Set the heat sealer’s temperature or timer according to the plastic thickness. Thicker bags need more heat or longer sealing time; thinner bags require less. Many sealers have adjustable settings or a dial. Test the heat on a scrap piece of the same bag material to find the right setting — the seal should be strong but not melted through.

Place the open end of the bag between the heat sealer’s sealing bars or plates. Align it straight and flat to avoid wrinkles, which can cause leaks. Close the sealer or press down the handle to apply heat and pressure.

Hold for the recommended duration — usually a few seconds. The heat melts the plastic edges, and pressure fuses them together. After the timer ends, release the handle or open the sealer. Let the seal cool and harden for a few seconds before handling.

Check the seal by gently pulling the bag edges. A good seal is uniform, smooth, and airtight. If you see gaps, wrinkles, or weak spots, reseal or adjust the temperature/time settings.

For larger bags or continuous sealing, some machines have conveyor belts or band sealers. Feed the bag through steadily for an even seal.

Seal Not Holding: If the seal peels apart easily, the heat or sealing time may be too low. Increase the temperature or hold time slightly and test again. Also, check if the sealing bars are clean.

Plastic Melting or Burning: Too much heat or too long a sealing time can melt the bag or cause holes. Lower the temperature or reduce sealing duration.

Wrinkles in Seal: Wrinkles weaken the seal and cause leaks. Make sure the bag is flat and taut before sealing. Avoid moving the bag during the sealing process.

Uneven Seal: This may happen if the sealing bars are misaligned or damaged. Inspect the bars and clean them regularly. Replace worn parts if needed.

Machine Not Heating: Confirm the sealer is plugged in and switched on. Check for blown fuses or faulty wiring in electric models. Some sealers have reset buttons or circuit breakers.

By following these steps and tips, you can achieve strong, airtight seals every time. Heat sealers provide a quick, reliable way to protect food, snacks, and other items from moisture and contamination. Regular maintenance and proper technique ensure your sealer works well for years.

When picking a sealer, think about what you’ll use it for most. Ask yourself:

What types of items will I seal? Perishable food like meat or veggies? Dry goods? Non-food items? Vacuum sealers are great for fresh foods needing longer storage. Heat sealers work well for dry or pre-packaged products.

How often will I use the sealer? If you seal daily or in bulk, a more durable, commercial-grade machine might be best. For occasional use, a basic or handheld model could suffice.

What’s my budget? Vacuum sealers often cost more upfront. Heat sealers usually come at lower prices. Factor in maintenance costs too.

Do I need portability? Consider where you’ll seal most — kitchen, workshop, or on the go. Handheld or compact models offer convenience but may have limited power.

What materials do I plan to seal? Some plastics only work with heat sealing, while vacuum sealers require special bags. Check compatibility before buying.

Portable Sealers

Small and lightweight.

Easy to carry or store.

Perfect for quick jobs or travel.

Usually handheld vacuum or heat sealers.

May have limited sealing strength or bag size capacity.

Stationary Sealers

Larger, heavier machines.

Designed for frequent or heavy-duty use.

Can handle bigger bags or containers.

Often come with more features like adjustable heat, vacuum strength, or sealing width.

Require dedicated space, usually on a countertop or workbench.

For example, a hunter might use a portable vacuum sealer in the field for quick packaging. A restaurant kitchen would benefit from a stationary chamber vacuum sealer for large batches.

Keeping your sealer in good shape ensures it lasts and works well:

Clean regularly: Wipe sealing bars, chambers, or plates after each use to remove residue or food particles. Use a damp cloth or mild cleaner.

Inspect sealing elements: Check for wear or damage on heating strips, gaskets, or vacuum pumps. Replace parts as needed to maintain strong seals.

Avoid overloading: Don’t try to seal bags that are too thick or overfilled. This can strain the machine and cause poor seals.

Store properly: Keep the sealer in a dry, dust-free place. Cover it if possible to prevent dirt buildup.

Follow manufacturer guidelines: Use recommended bags and settings. Refer to the manual for troubleshooting and routine care.

Test periodically: Run test seals on scrap material to confirm the machine works correctly before sealing important items.

By weighing your sealing needs, usage frequency, and budget, you can choose the right sealer. Maintaining it well keeps your investment working efficiently for years. Whether you pick a vacuum or heat sealer, the right tool makes food preservation and packaging easier and more effective.

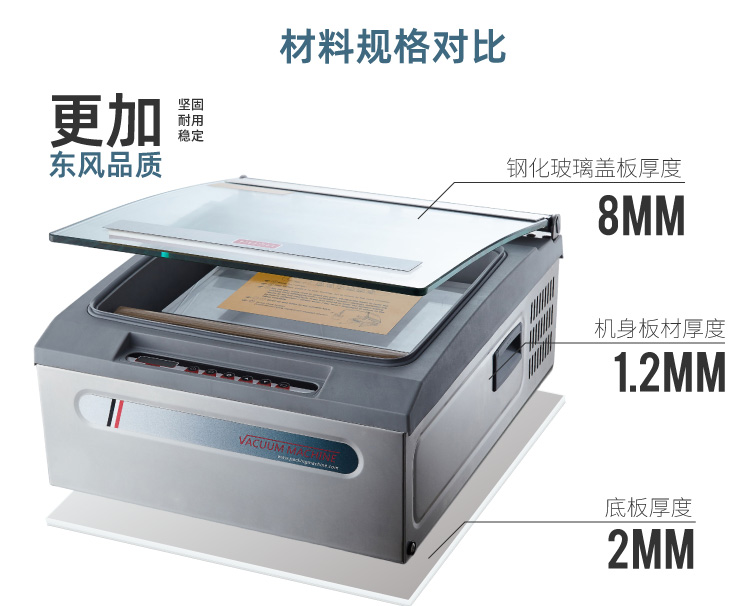

Vacuum sealers remove air to preserve food, while heat sealers use heat to create airtight seals. Vacuum sealers are ideal for long-term food preservation, whereas heat sealers excel in quick sealing tasks. Choosing the right sealer depends on your specific needs, usage frequency, and budget. Zhejiang DongFeng Packing Machine Co., Ltd. offers high-quality sealing solutions, ensuring efficient food preservation and packaging. Their products provide value through durability and reliability, making them a smart choice for effective sealing.

A: A vacuum sealer removes air from packaging to preserve food freshness and prevent spoilage.

A: Heat sealers can seal plastic bags for food, medical supplies, electronics, and other products needing protection.

A: Vacuum sealers remove air before sealing, while heat sealers use heat to fuse plastic edges without air removal.

A: Consider the types of items, frequency of use, budget, portability, and material compatibility.