loading

| Availability: | |

|---|---|

| Quantity: | |

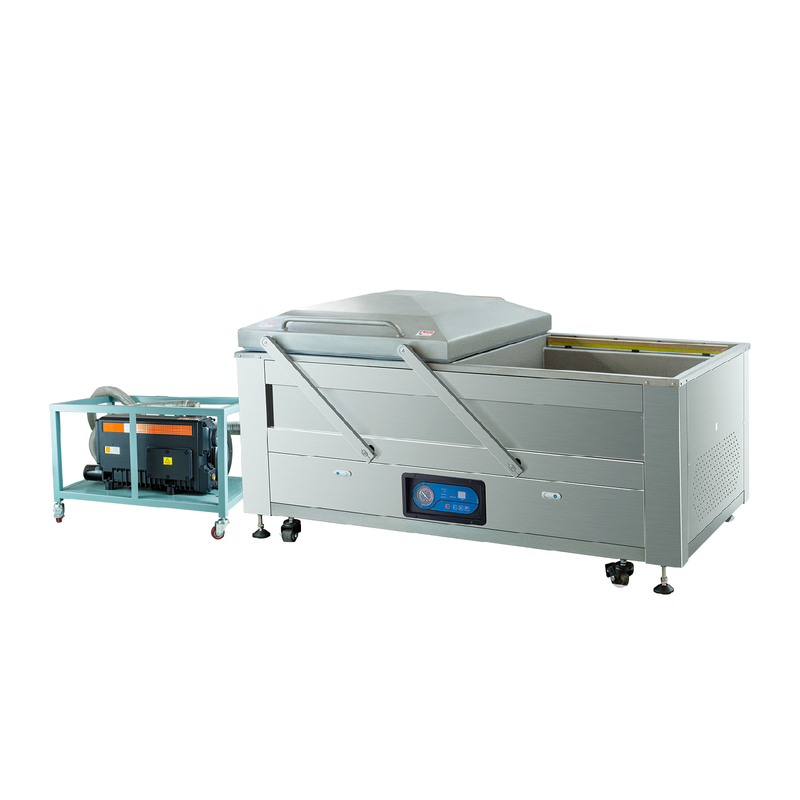

DZQ-900/2SA

DFPACK

Meat, Seafood, Cooked Food, Fruits and Vegetables, Granules, Liquids, Powders, Medical Equipment, Hardware

Pouch

Vacuum Packaging

High

The vacuum sealer machine is made of 96% stainless steel.

The meat vacuum packing machine features patented technology, allowing the easy transfer of the 900-type vacuum cover to another chamber.

The double chamber vacuum packing machine can be customized with a vacuum chamber depth of up to 350mm.

The vacuum sealer machine can be equipped with vacuum pumps ranging from 100 to 400m³; larger m³ indicates greater suction power.

The industrial vacuum packing machine uses a concave vacuum chamber to effectively address product space issues.

The vacuum packing machine is controlled by a PCB board.

The vacuum sealer offers an optional gas flushing feature.

The meat vacuum packing machine has a plug-in sealing strip for easier replacement of heating wires.

It includes a separate electrical box for quicker maintenance and inspection.

| Model | DZQ-900/2SA |

| Voltage | 3phase 220/380V 50-60Hz |

| Pump Power | 4kw |

| Pump Capacity | 200m³/h /Option |

| Sealing Length | 900mm(x4) |

| Sealing Width | 10mm |

| Chamber Size | 1000x850x350mm |

| Dimension | 2145x1100x1155mm |

| Weigth | ≈550kgs |

| Certification | CE ISO |

WHERE INNOVATION MEETS YOUR NEEDS.

Ten Strengths, One Unstoppable Solution. 10X the Benefits, Zero Compromise

THE VACUUM CHAMBER IS EXTRA DEEP

The deep vacuum chamber accommodates larger items and ensures tighter sealing for bulkier products.

NICKEL-CHROMIUM ALLOY

High temperature and anti-oxidation resistance, Prolong the service life of electric heating wire,Effectively reduce the consumable replacement rate

MATERIAL SPECIFICATIONS

The machine body is made of durable 304 stainless steel

Robust stainless steel structure withstands 100,000+ closures

FDA-grade silicone seals with <0.05% leakage rate (1 spare set included)

Use an external vacuum pump to free up space for the vacuum chamber

In-house R&D team support Adjustable chamber sizes

SEALING DESIGN

Insert and pull sealing strip for easy replacement

MOVABLE

The machine and pump have swivel casters for easy movement on flat surfaces.

COMPLETE STAINLESS STEEL STRUCTURE FOR MAX DURABILITY

Prevent electronic and parts from oxidation

INDUSTRIAL VACUUM SYSTEM

Anti-corrosion pump with wear-resistant blades for extended heavy-duty operation

DONGFENG'S COPPER-CORE TRANSFORMERS

Dual pure-coil transformers ensure maximum conductivity + heat resistance for stable operation.vs Budget Aluminum Transformers Lower-cost machines use aluminum coils, increasing resistance and fatigue failure risk during continuous use.

| Copper wire transformer | What are the differences between copper and aluminum transformers | Aluminum wire transformer |

| strong | Electrical conductivity | weak |

| high | Fusing point | low |

| strong | Short-circuit resistance | weak |

| higher | Mechanical strength | lower |

| low | Electrical resistivity | Easy to increase |

INDUSTRIAL-GRADE SOLENOID VALVES

Dongfeng machines feature large solenoid valves for accelerated pumping, sustained efficiency, and stable sealing quality.

OUT OF THE BOX

No installation required

The vacuum sealer machine is made of 96% stainless steel.

The meat vacuum packing machine features patented technology, allowing the easy transfer of the 900-type vacuum cover to another chamber.

The double chamber vacuum packing machine can be customized with a vacuum chamber depth of up to 350mm.

The vacuum sealer machine can be equipped with vacuum pumps ranging from 100 to 400m³; larger m³ indicates greater suction power.

The industrial vacuum packing machine uses a concave vacuum chamber to effectively address product space issues.

The vacuum packing machine is controlled by a PCB board.

The vacuum sealer offers an optional gas flushing feature.

The meat vacuum packing machine has a plug-in sealing strip for easier replacement of heating wires.

It includes a separate electrical box for quicker maintenance and inspection.

| Model | DZQ-900/2SA |

| Voltage | 3phase 220/380V 50-60Hz |

| Pump Power | 4kw |

| Pump Capacity | 200m³/h /Option |

| Sealing Length | 900mm(x4) |

| Sealing Width | 10mm |

| Chamber Size | 1000x850x350mm |

| Dimension | 2145x1100x1155mm |

| Weigth | ≈550kgs |

| Certification | CE ISO |

WHERE INNOVATION MEETS YOUR NEEDS.

Ten Strengths, One Unstoppable Solution. 10X the Benefits, Zero Compromise

THE VACUUM CHAMBER IS EXTRA DEEP

The deep vacuum chamber accommodates larger items and ensures tighter sealing for bulkier products.

NICKEL-CHROMIUM ALLOY

High temperature and anti-oxidation resistance, Prolong the service life of electric heating wire,Effectively reduce the consumable replacement rate

MATERIAL SPECIFICATIONS

The machine body is made of durable 304 stainless steel

Robust stainless steel structure withstands 100,000+ closures

FDA-grade silicone seals with <0.05% leakage rate (1 spare set included)

Use an external vacuum pump to free up space for the vacuum chamber

In-house R&D team support Adjustable chamber sizes

SEALING DESIGN

Insert and pull sealing strip for easy replacement

MOVABLE

The machine and pump have swivel casters for easy movement on flat surfaces.

COMPLETE STAINLESS STEEL STRUCTURE FOR MAX DURABILITY

Prevent electronic and parts from oxidation

INDUSTRIAL VACUUM SYSTEM

Anti-corrosion pump with wear-resistant blades for extended heavy-duty operation

DONGFENG'S COPPER-CORE TRANSFORMERS

Dual pure-coil transformers ensure maximum conductivity + heat resistance for stable operation.vs Budget Aluminum Transformers Lower-cost machines use aluminum coils, increasing resistance and fatigue failure risk during continuous use.

| Copper wire transformer | What are the differences between copper and aluminum transformers | Aluminum wire transformer |

| strong | Electrical conductivity | weak |

| high | Fusing point | low |

| strong | Short-circuit resistance | weak |

| higher | Mechanical strength | lower |

| low | Electrical resistivity | Easy to increase |

INDUSTRIAL-GRADE SOLENOID VALVES

Dongfeng machines feature large solenoid valves for accelerated pumping, sustained efficiency, and stable sealing quality.

OUT OF THE BOX

No installation required