loading

| Availability: | |

|---|---|

| Quantity: | |

BS-250

DFPACK

Boxes

Cartons

Shrink Packaging

Medium

The BS-250 Heat Shrink Packaging Machine uses heat shrink technology to tightly wrap plastic film around the product surface, enhancing its appearance while providing an additional layer of protection.

Multiple Heating Tubes: The shrink wrapping machine is equipped with multiple heating tubes, ensuring even heat distribution and improved overall efficiency.

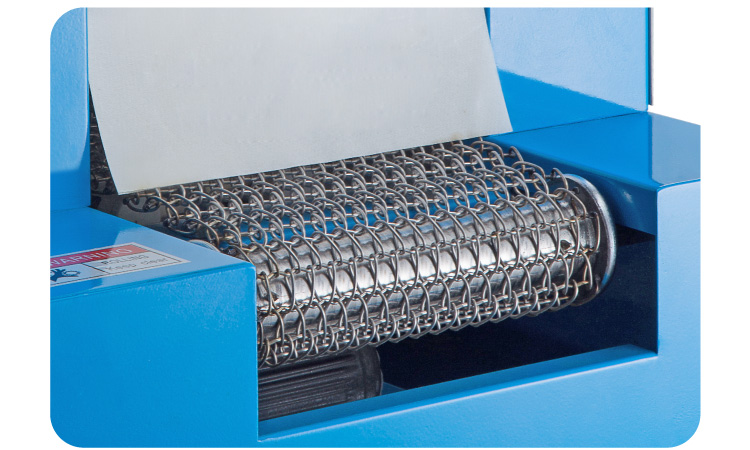

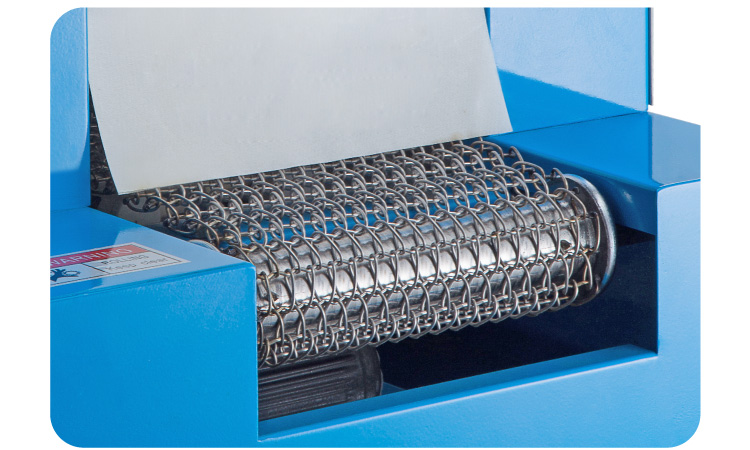

Optional Conveyor Systems: The shrink wrapping machine can be fitted with mesh, chain, or shaft-type conveyors, offering flexibility to meet different production environments.

Modern Design: The shrink wrapping machine features a sleek and modern design that aligns with industrial aesthetics, enhancing the overall appearance of the equipment.

Cost-Effective: It provides excellent value for money, making it suitable for businesses of all sizes while reducing production costs and delivering high-quality packaging results.

The Shrink Wrapping Machine is an efficient automated device designed to tightly wrap products with heat shrink film. By heating the shrink film and ensuring it conforms tightly to the product's surface, it creates a strong protective seal that safeguards the product from external elements. The machine is suitable for packaging products of various shapes and sizes and is widely used in the food, beverage, consumer goods, and industrial sectors. The Shrink Wrapping Machine not only enhances production efficiency but also guarantees aesthetically pleasing and durable packaging, making it ideal for large-scale production.

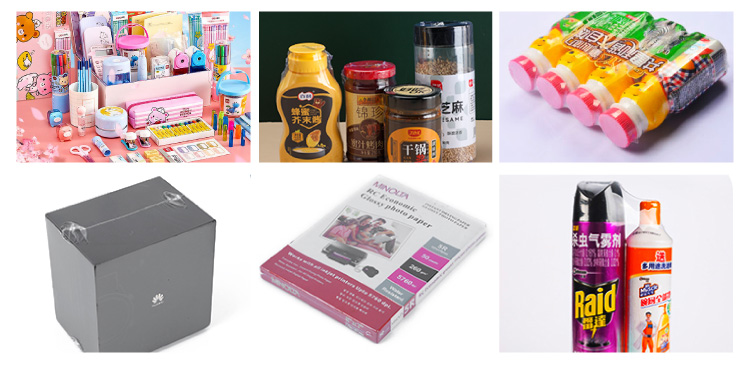

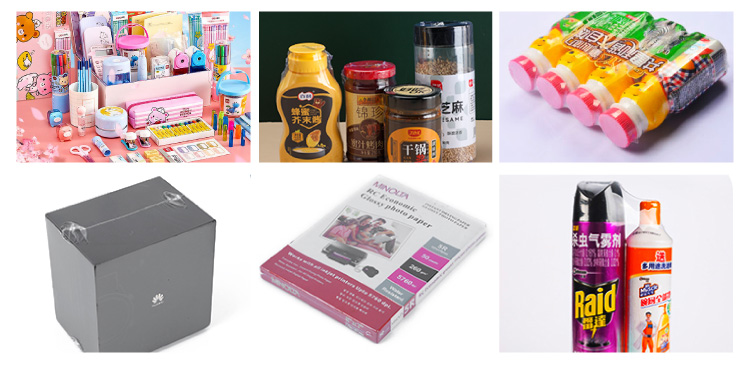

The Shrink Wrapping Machine is suitable for:

Food Packaging: Wrapping beverage bottles, snack bags, frozen foods, instant noodles, etc.

Consumer Goods Packaging: Packaging personal care products, cleaning supplies, cosmetics, etc.

Industrial Products Packaging: Wrapping electronic devices, machinery parts, hardware tools, toys, etc.

Gift Packaging: Packaging various gift items with a perfect presentation, adding value to the products.

High Production Efficiency

The automated process accelerates packaging speed, significantly improving production efficiency and reducing labor costs, making it ideal for large-scale production.

Precise Sealing

The heat shrink film is evenly heated and shrunk, ensuring that it tightly adheres to the product's surface, providing excellent moisture, dust, and theft protection.

Wide Product Applicability

Suitable for products of various shapes and sizes, the machine can handle both single-item and multi-pack packaging, ensuring perfect results for different packaging needs.

Ease of Operation

The shrink wrapping machine is designed to be user-friendly, with minimal technical knowledge required, allowing employees to quickly learn and operate the machine.

Aesthetic Packaging

The shrink film wraps tightly around the product, creating a smooth, neat appearance that enhances the product’s market appeal and competitiveness.

Energy Efficient

The efficient heating system ensures optimal energy usage, delivering excellent packaging results while minimizing energy consumption and reducing production costs.

Durable and Reliable

Built with high-quality materials and advanced manufacturing techniques, the machine is durable and reliable, with a long service life, minimizing maintenance and replacement costs.

Model | BS-250 |

| Voltage | 110/220 V 50-60 Hz |

| Pump Power | 3kw |

| Shink Time | 0.6p/min |

| Weight | 88.2 lb 40 kgs |

| Certification | CE ISO |

MAXIMUM PACKAGE SIZE

| max width: | 9.8 inch(250mm) |

| max height: | 5.9 inch(150mm) |

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

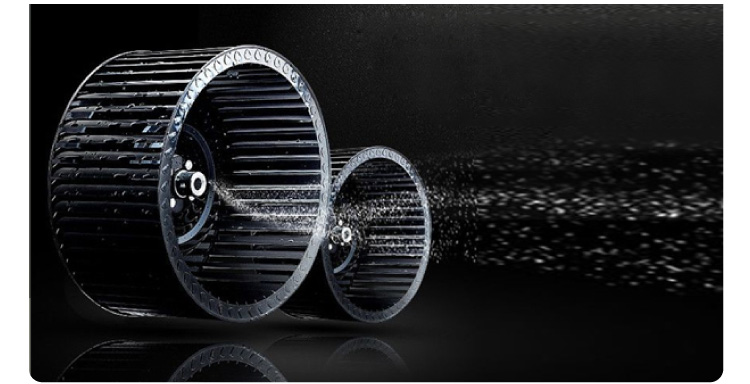

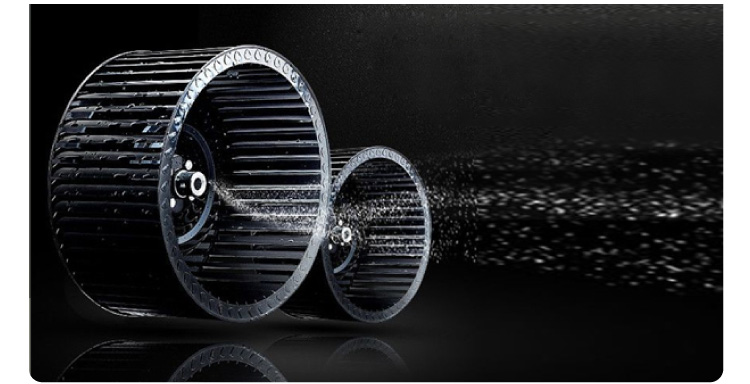

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials Keep the furnace temperature uniform

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design, and the entrance adopts high temperature cloth as cover, which makes the equipment safer during operation!

APPLICATION

OUT OF THE BOX

No installation required

Multiple Heating Tubes: The shrink wrapping machine is equipped with multiple heating tubes, ensuring even heat distribution and improved overall efficiency.

Optional Conveyor Systems: The shrink wrapping machine can be fitted with mesh, chain, or shaft-type conveyors, offering flexibility to meet different production environments.

Modern Design: The shrink wrapping machine features a sleek and modern design that aligns with industrial aesthetics, enhancing the overall appearance of the equipment.

Cost-Effective: It provides excellent value for money, making it suitable for businesses of all sizes while reducing production costs and delivering high-quality packaging results.

The Shrink Wrapping Machine is an efficient automated device designed to tightly wrap products with heat shrink film. By heating the shrink film and ensuring it conforms tightly to the product's surface, it creates a strong protective seal that safeguards the product from external elements. The machine is suitable for packaging products of various shapes and sizes and is widely used in the food, beverage, consumer goods, and industrial sectors. The Shrink Wrapping Machine not only enhances production efficiency but also guarantees aesthetically pleasing and durable packaging, making it ideal for large-scale production.

The Shrink Wrapping Machine is suitable for:

Food Packaging: Wrapping beverage bottles, snack bags, frozen foods, instant noodles, etc.

Consumer Goods Packaging: Packaging personal care products, cleaning supplies, cosmetics, etc.

Industrial Products Packaging: Wrapping electronic devices, machinery parts, hardware tools, toys, etc.

Gift Packaging: Packaging various gift items with a perfect presentation, adding value to the products.

High Production Efficiency

The automated process accelerates packaging speed, significantly improving production efficiency and reducing labor costs, making it ideal for large-scale production.

Precise Sealing

The heat shrink film is evenly heated and shrunk, ensuring that it tightly adheres to the product's surface, providing excellent moisture, dust, and theft protection.

Wide Product Applicability

Suitable for products of various shapes and sizes, the machine can handle both single-item and multi-pack packaging, ensuring perfect results for different packaging needs.

Ease of Operation

The shrink wrapping machine is designed to be user-friendly, with minimal technical knowledge required, allowing employees to quickly learn and operate the machine.

Aesthetic Packaging

The shrink film wraps tightly around the product, creating a smooth, neat appearance that enhances the product’s market appeal and competitiveness.

Energy Efficient

The efficient heating system ensures optimal energy usage, delivering excellent packaging results while minimizing energy consumption and reducing production costs.

Durable and Reliable

Built with high-quality materials and advanced manufacturing techniques, the machine is durable and reliable, with a long service life, minimizing maintenance and replacement costs.

Model | BS-250 |

| Voltage | 110/220 V 50-60 Hz |

| Pump Power | 3kw |

| Shink Time | 0.6p/min |

| Weight | 88.2 lb 40 kgs |

| Certification | CE ISO |

MAXIMUM PACKAGE SIZE

| max width: | 9.8 inch(250mm) |

| max height: | 5.9 inch(150mm) |

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials Keep the furnace temperature uniform

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design, and the entrance adopts high temperature cloth as cover, which makes the equipment safer during operation!

APPLICATION

OUT OF THE BOX

No installation required