loading

| Availability: | |

|---|---|

| Quantity: | |

BS-400LD

DFPACK

Boxes

Cartons

Shrink Packaging

Medium

The BS-400 LD Heat Shrink Packaging Machine uses heat shrink technology to tightly wrap plastic film around the product surface, enhancing its appearance while providing an additional layer of protection.

Efficient Heating System

The machine utilizes advanced heating technology, ensuring the heat shrink film is evenly heated and quickly shrunk, reducing production time and improving efficiency.

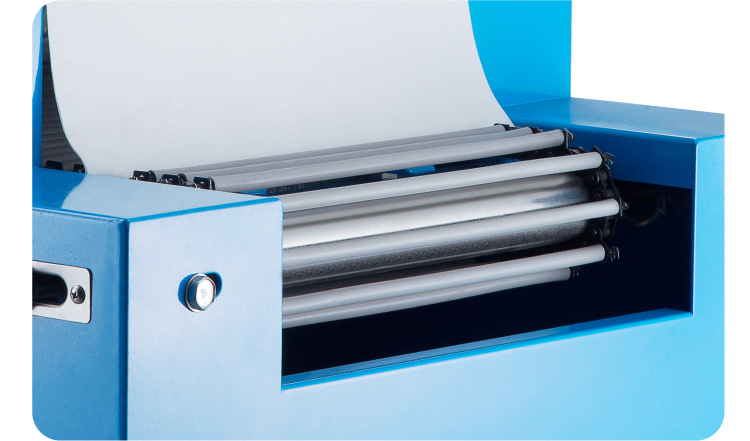

Customizable Conveyor Options

The automatic shrink wrapping machine offers a variety of conveyor options, including mesh, chain, and shaft types, allowing customization to meet specific production needs, enhancing the efficiency of the production line.

Compact Design for Space Optimization

The compact design of the machine saves space, making it ideal for environments with limited space, and well-suited for small and medium-sized production lines.

Affordable and Reliable

This heat shrink machine provides a cost-effective solution for businesses of all sizes, ensuring durability and reliable performance while maintaining a budget-friendly price.

The Shrink Wrapping Machine is an advanced automated packaging device designed to efficiently apply heat shrink film around products. By heating the film, the machine causes it to shrink tightly around the product, creating a strong protective seal that prevents dust, moisture, and other contaminants. This machine is versatile and can handle products of various sizes and shapes, making it ideal for industries such as food, consumer goods, electronics, and industrial products. The Shrink Wrapping Machine improves packaging efficiency and significantly enhances product presentation, making it an ideal choice for high-volume production lines.

The Shrink Wrapping Machine is suitable for:

Food Packaging: Packaging biscuits, candies, bottled beverages, frozen food, and other food products to maintain freshness and prevent contamination.

Consumer Goods: Packaging household items, stationery, toys, and other retail products.

Electronics Packaging: Wrapping electronic components, mobile accessories, computer hardware, and other products that need protection from moisture and contamination.

Industrial Packaging: Packaging tools, machine parts, workshop components, and other industrial products that require protection during transportation or storage.

Fast Packaging Process

The machine's fully automated operation significantly speeds up the packaging process, reducing labor costs and boosting productivity, making it ideal for high-volume production.

Precise and Secure Packaging

The shrink film tightly conforms to the product's shape, creating a strong seal that offers excellent protection against moisture, dust, and damage.

Versatility for Various Products

Whether for small or large items, the shrink wrapping machine can easily handle a wide range of products, providing a perfect solution for different industries and packaging requirements.

User-Friendly Operation

The simple and intuitive control interface makes the machine easy to operate, even for workers without specialized training, reducing human errors and downtime.

Enhanced Product Appearance

The shrink film tightly wraps around the product, creating a smooth, professional appearance that enhances product appeal and makes it stand out on store shelves.

Energy-Efficient Design

The automatic shrink wrapping machine is designed with energy-saving features, reducing power consumption while still providing excellent performance, making it an ideal choice for businesses looking to reduce energy costs.

Durable Construction, Low Maintenance

Built with high-quality materials, the shrink wrapping machine is durable and requires minimal maintenance, offering long-lasting, reliable performance and reducing operational costs.

Model | BS-400LD |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 6.5kw |

| Shink Time | 0-10p/min |

| Weight | 187.4 lb 85 kgs |

| Certification | CE ISO |

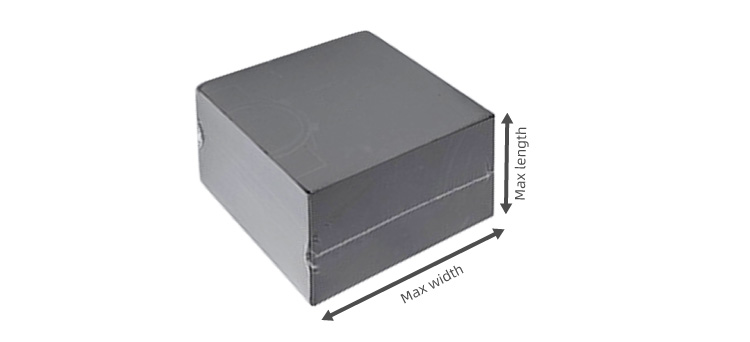

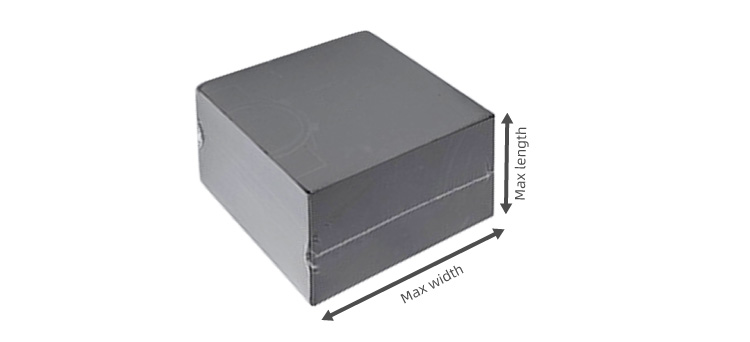

MAXIMUM PACKAGE SIZE

| max width: | 15.7 inch(400mm) |

| max height: | 7.9 inch(200mm) |

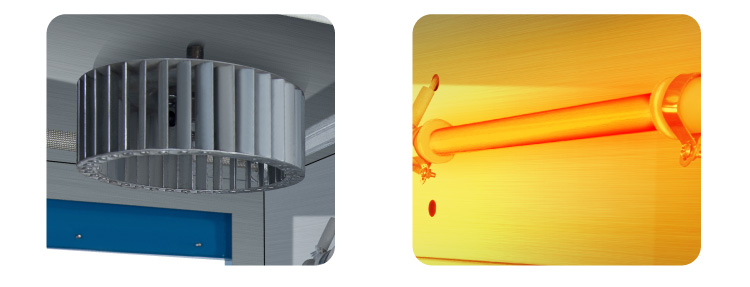

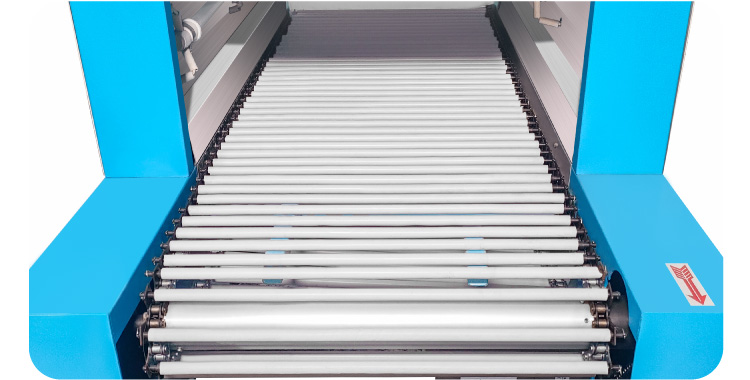

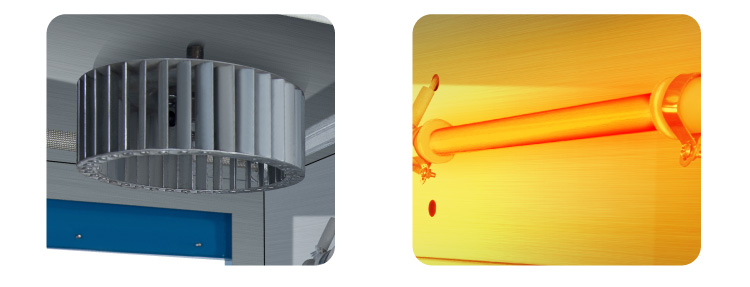

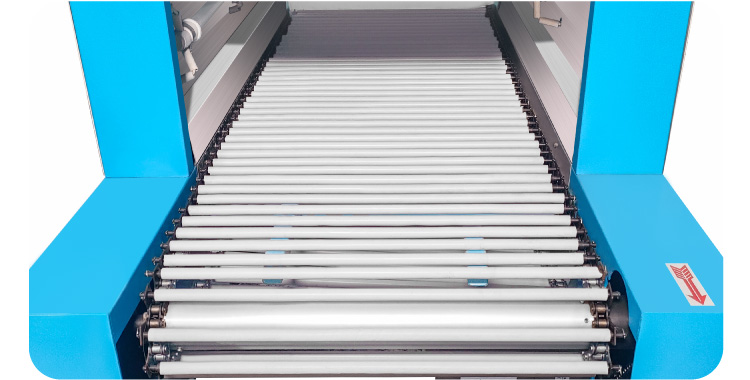

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

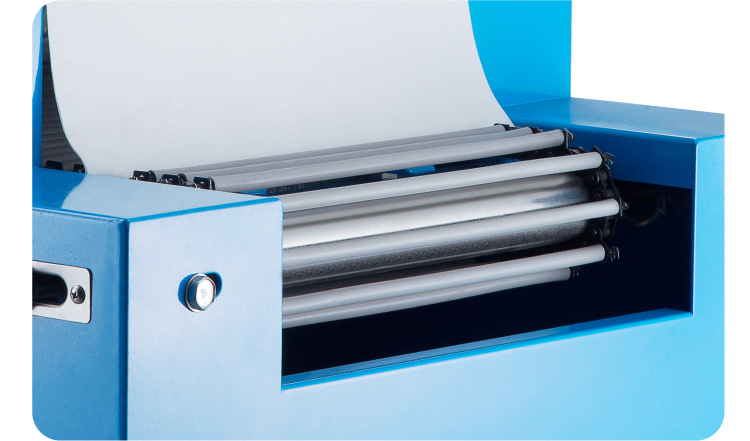

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

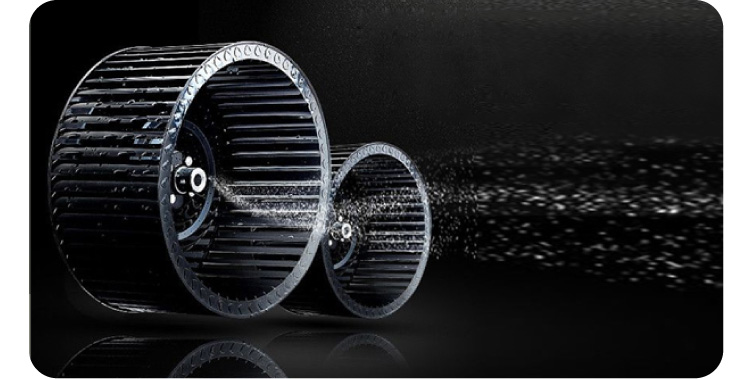

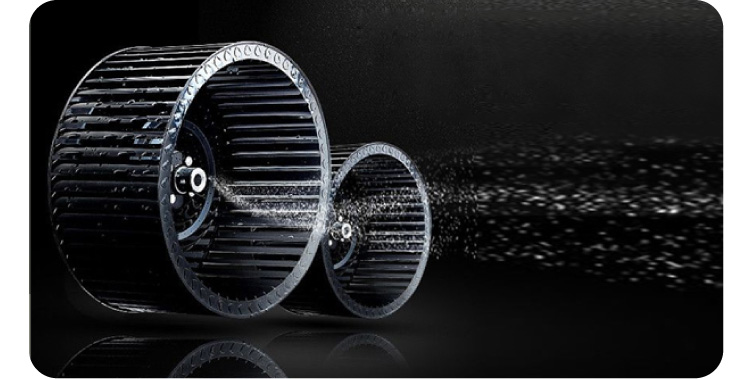

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

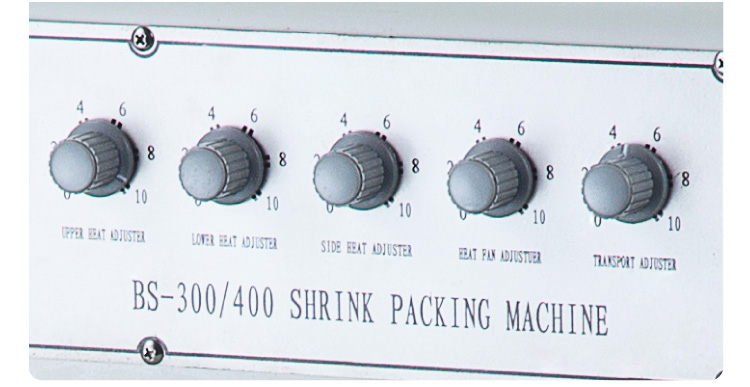

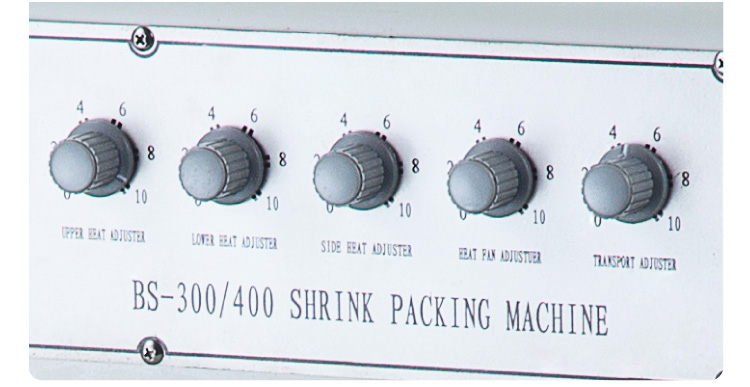

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials

Keep the furnace temperature uniform

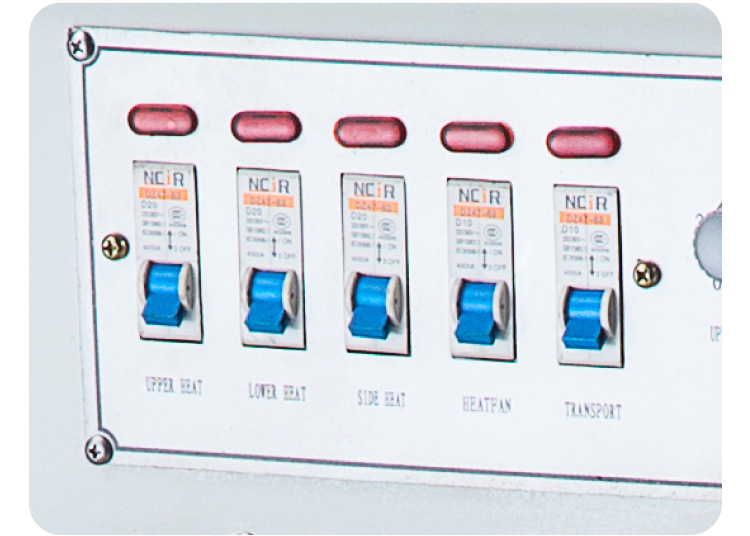

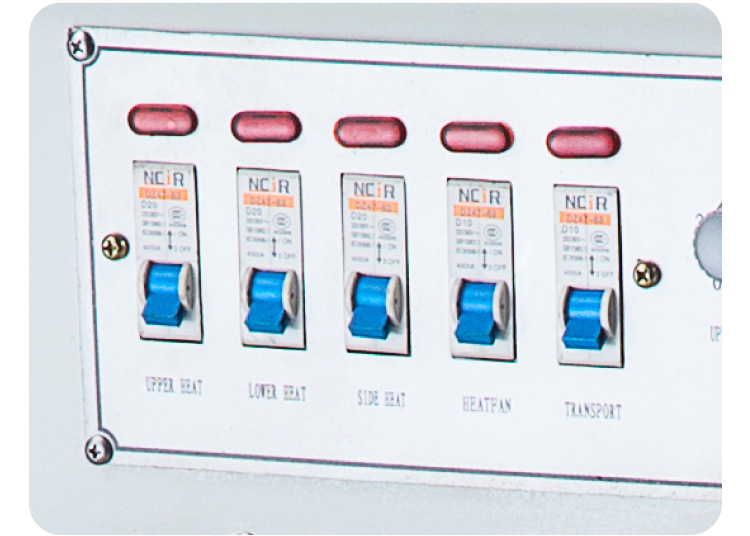

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design, and the entrance adopts high temperature cloth as cover, which makes the equipment safer during operation!

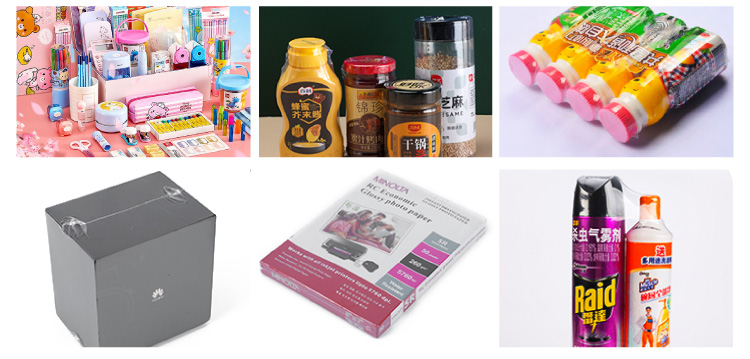

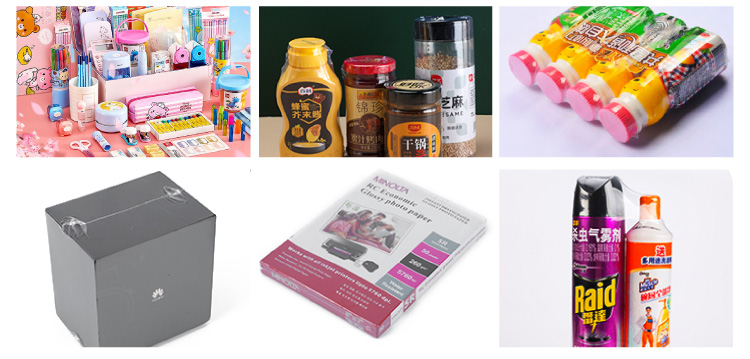

APPLICATION

OUT OF THE BOX

No installation require

Efficient Heating System

The machine utilizes advanced heating technology, ensuring the heat shrink film is evenly heated and quickly shrunk, reducing production time and improving efficiency.

Customizable Conveyor Options

The automatic shrink wrapping machine offers a variety of conveyor options, including mesh, chain, and shaft types, allowing customization to meet specific production needs, enhancing the efficiency of the production line.

Compact Design for Space Optimization

The compact design of the machine saves space, making it ideal for environments with limited space, and well-suited for small and medium-sized production lines.

Affordable and Reliable

This heat shrink machine provides a cost-effective solution for businesses of all sizes, ensuring durability and reliable performance while maintaining a budget-friendly price.

The Shrink Wrapping Machine is an advanced automated packaging device designed to efficiently apply heat shrink film around products. By heating the film, the machine causes it to shrink tightly around the product, creating a strong protective seal that prevents dust, moisture, and other contaminants. This machine is versatile and can handle products of various sizes and shapes, making it ideal for industries such as food, consumer goods, electronics, and industrial products. The Shrink Wrapping Machine improves packaging efficiency and significantly enhances product presentation, making it an ideal choice for high-volume production lines.

The Shrink Wrapping Machine is suitable for:

Food Packaging: Packaging biscuits, candies, bottled beverages, frozen food, and other food products to maintain freshness and prevent contamination.

Consumer Goods: Packaging household items, stationery, toys, and other retail products.

Electronics Packaging: Wrapping electronic components, mobile accessories, computer hardware, and other products that need protection from moisture and contamination.

Industrial Packaging: Packaging tools, machine parts, workshop components, and other industrial products that require protection during transportation or storage.

Fast Packaging Process

The machine's fully automated operation significantly speeds up the packaging process, reducing labor costs and boosting productivity, making it ideal for high-volume production.

Precise and Secure Packaging

The shrink film tightly conforms to the product's shape, creating a strong seal that offers excellent protection against moisture, dust, and damage.

Versatility for Various Products

Whether for small or large items, the shrink wrapping machine can easily handle a wide range of products, providing a perfect solution for different industries and packaging requirements.

User-Friendly Operation

The simple and intuitive control interface makes the machine easy to operate, even for workers without specialized training, reducing human errors and downtime.

Enhanced Product Appearance

The shrink film tightly wraps around the product, creating a smooth, professional appearance that enhances product appeal and makes it stand out on store shelves.

Energy-Efficient Design

The automatic shrink wrapping machine is designed with energy-saving features, reducing power consumption while still providing excellent performance, making it an ideal choice for businesses looking to reduce energy costs.

Durable Construction, Low Maintenance

Built with high-quality materials, the shrink wrapping machine is durable and requires minimal maintenance, offering long-lasting, reliable performance and reducing operational costs.

Model | BS-400LD |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 6.5kw |

| Shink Time | 0-10p/min |

| Weight | 187.4 lb 85 kgs |

| Certification | CE ISO |

MAXIMUM PACKAGE SIZE

| max width: | 15.7 inch(400mm) |

| max height: | 7.9 inch(200mm) |

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials

Keep the furnace temperature uniform

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design, and the entrance adopts high temperature cloth as cover, which makes the equipment safer during operation!

APPLICATION

OUT OF THE BOX

No installation require