loading

| Availability: | |

|---|---|

| Quantity: | |

BS-450

DFPACK

Boxes

Cartons

Shrink Packaging

Medium

The BS-450 LD Shrink Wrapping Machine provides an economical, efficient, and customizable solution for a variety of packaging needs.

Efficient and Quick Shrinkage

The Shrink Wrapping Machine is equipped with an advanced heating system that ensures rapid and even heat distribution. This allows the shrink film to tightly conform to the product's shape, providing a secure and smooth finish. Fast shrinkage speeds up the packaging process and reduces production time.

Customizable Conveyor Options

The automatic shrink wrapping machine can be fitted with various conveyor types, including mesh, chain, and roller systems, tailored to meet the unique demands of each production line. This flexibility ensures smooth and efficient transport of products through the machine.

Compact Footprint

Designed with space optimization in mind, the Shrink Wrapping Machine’s compact structure allows it to fit seamlessly into tight production spaces, making it a great option for businesses with limited floor area.

Cost-Effective Operation

This heat shrink machine provides an affordable packaging solution without compromising on quality or performance. The low maintenance requirements and minimal energy consumption help reduce long-term operational costs, making it an ideal choice for both small and large businesses.

The Shrink Wrapping Machine is a cutting-edge packaging solution designed to apply heat shrink film tightly around products, ensuring secure, durable, and protective packaging. The machine utilizes heat to shrink the film around items, providing a tight seal that protects them from moisture, dust, and contaminants while maintaining product integrity. It is highly adaptable and can handle a wide variety of product shapes and sizes, making it ideal for industries such as food packaging, cosmetics, electronics, and retail. The Shrink Wrapping Machine is engineered for efficiency, enabling high-speed packaging in large volumes, making it an essential tool for businesses aiming to improve packaging efficiency and product presentation.

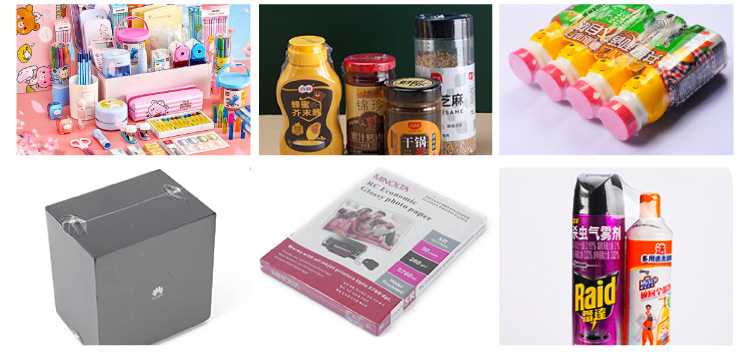

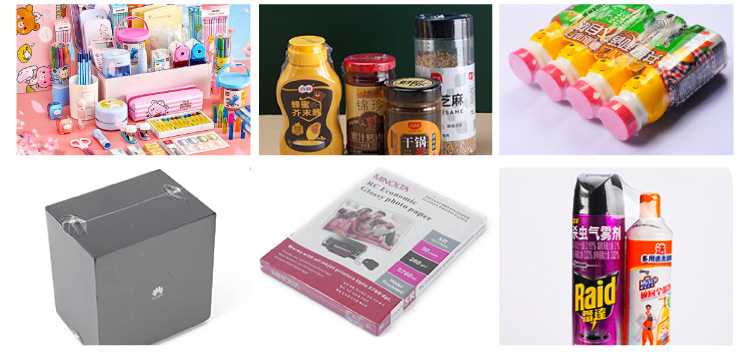

The Shrink Wrapping Machine is suitable for:

Food Packaging: Wrapping packaged food items such as beverages, snacks, fresh produce, and ready-to-eat meals to preserve quality and prevent contamination.

Cosmetics and Personal Care: Wrapping skincare products, makeup items, shampoos, and other toiletries to ensure hygiene and protection.

Electronics: Packaging electronic components, devices, and accessories to protect them from environmental factors like moisture and dust.

Retail & Promotional Packaging: Packaging multi-item bundles, promotional packs, and gift sets for an attractive presentation on store shelves.

High-Speed Automated Operation

The fully automated nature of the machine allows for high-speed packaging, significantly increasing production capacity and reducing labor costs. This ensures a high output in a short amount of time, perfect for businesses with large-scale production requirements.

Durable, Secure Packaging

The shrink film tightly hugs the product, providing a tamper-evident and durable seal. This offers superior protection against external contaminants such as moisture, dust, and dirt, ensuring the product reaches customers in perfect condition.

Versatile Handling of Various Products

Whether it’s irregularly shaped items or multiple products packed together, the Shrink Wrapping Machine is capable of handling a wide range of product types, making it highly adaptable to different industries.

User-Friendly Interface

The shrink wrapping machine features an intuitive control panel with easy-to-understand functions, enabling operators to quickly learn how to use it. This reduces the need for extensive training and minimizes the chance of user error.

Improved Visual Appeal

The tight, flawless shrink film enhances the appearance of the product, creating a smooth and professional finish that attracts customers. This improved presentation helps boost the product's shelf appeal and marketability.

Energy-Saving Technology

The Shrink Wrapping Machine is designed to operate with minimal energy consumption, reducing operational costs while maintaining high performance. This energy efficiency makes it an excellent choice for businesses aiming to cut down on electricity costs.

Robust and Low Maintenance

Built with high-quality materials and advanced engineering, the machine is highly durable and requires minimal maintenance, resulting in fewer repairs and downtime. This ensures consistent performance and long-term reliability.

Model | BS-450 |

| Votalge | 110/220V 50-60Hz |

| Pump Power | 7.5kw |

| Shink Time | 0-10p/min |

| Weight | 220.5 lb 100 kgs |

| Certification | CE ISO |

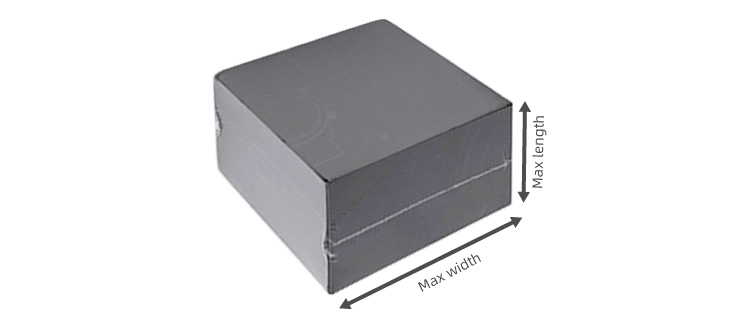

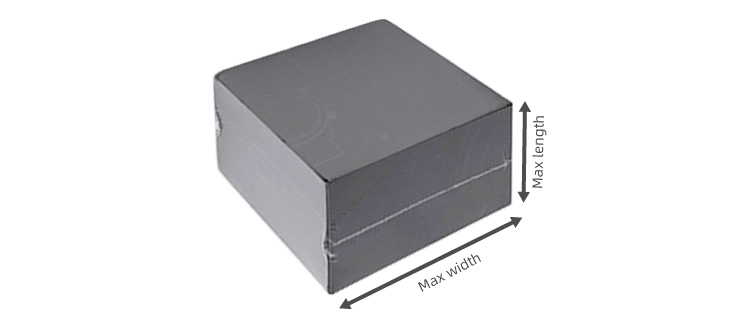

MAXIMUM PACKAGE SIZE

| max width: | 17.7 inch(450mm) |

| max height: | 9.8 inch(250mm) |

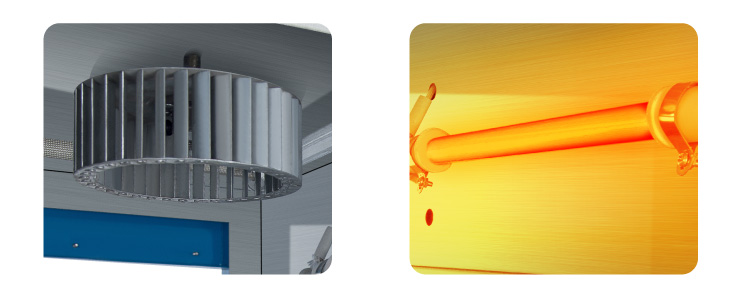

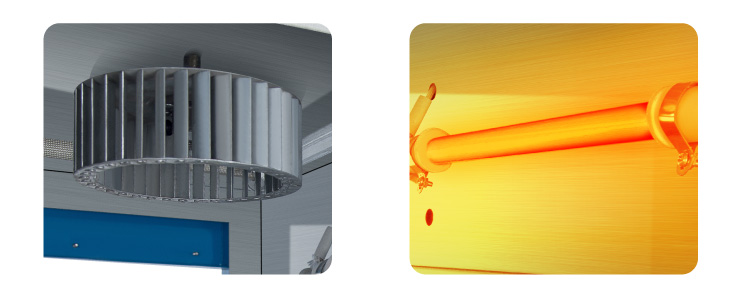

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

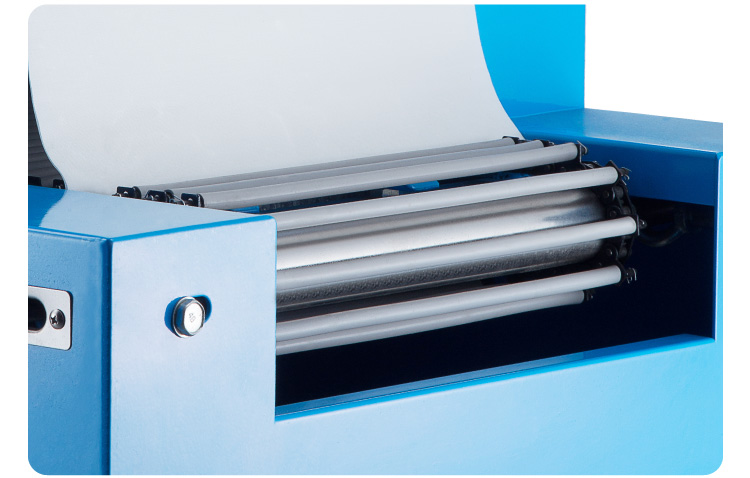

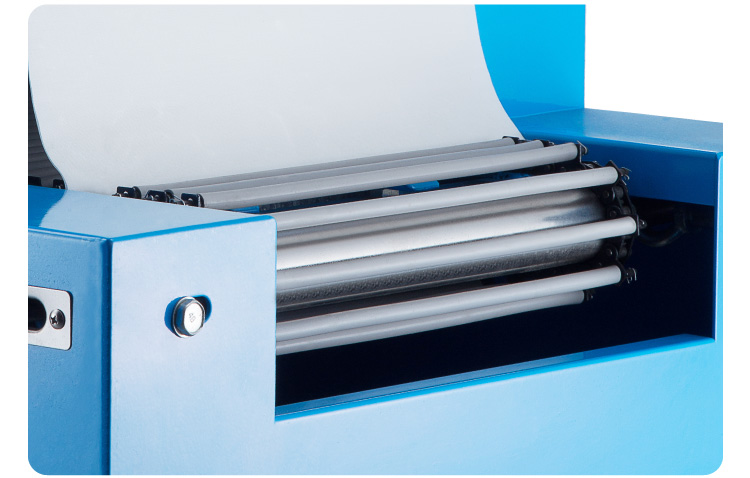

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

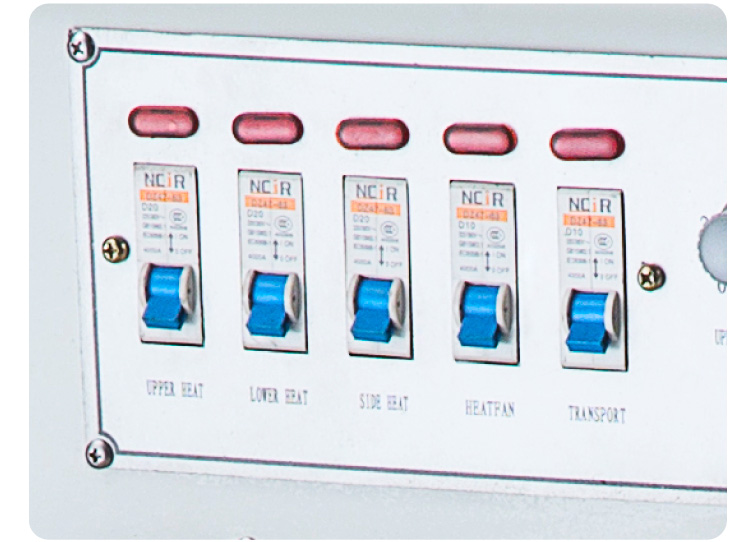

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials

Keep the furnace temperature uniform

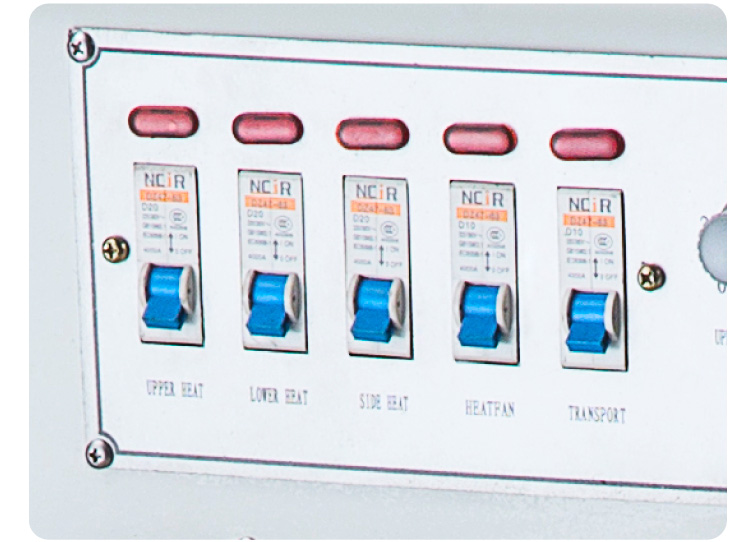

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design,

and the entrance adopts high temperature cloth as cover,

which makes the equipment safer during operation!

APPLICATION

OUT OF THE BOX

No installation required

Efficient and Quick Shrinkage

The Shrink Wrapping Machine is equipped with an advanced heating system that ensures rapid and even heat distribution. This allows the shrink film to tightly conform to the product's shape, providing a secure and smooth finish. Fast shrinkage speeds up the packaging process and reduces production time.

Customizable Conveyor Options

The automatic shrink wrapping machine can be fitted with various conveyor types, including mesh, chain, and roller systems, tailored to meet the unique demands of each production line. This flexibility ensures smooth and efficient transport of products through the machine.

Compact Footprint

Designed with space optimization in mind, the Shrink Wrapping Machine’s compact structure allows it to fit seamlessly into tight production spaces, making it a great option for businesses with limited floor area.

Cost-Effective Operation

This heat shrink machine provides an affordable packaging solution without compromising on quality or performance. The low maintenance requirements and minimal energy consumption help reduce long-term operational costs, making it an ideal choice for both small and large businesses.

The Shrink Wrapping Machine is a cutting-edge packaging solution designed to apply heat shrink film tightly around products, ensuring secure, durable, and protective packaging. The machine utilizes heat to shrink the film around items, providing a tight seal that protects them from moisture, dust, and contaminants while maintaining product integrity. It is highly adaptable and can handle a wide variety of product shapes and sizes, making it ideal for industries such as food packaging, cosmetics, electronics, and retail. The Shrink Wrapping Machine is engineered for efficiency, enabling high-speed packaging in large volumes, making it an essential tool for businesses aiming to improve packaging efficiency and product presentation.

The Shrink Wrapping Machine is suitable for:

Food Packaging: Wrapping packaged food items such as beverages, snacks, fresh produce, and ready-to-eat meals to preserve quality and prevent contamination.

Cosmetics and Personal Care: Wrapping skincare products, makeup items, shampoos, and other toiletries to ensure hygiene and protection.

Electronics: Packaging electronic components, devices, and accessories to protect them from environmental factors like moisture and dust.

Retail & Promotional Packaging: Packaging multi-item bundles, promotional packs, and gift sets for an attractive presentation on store shelves.

High-Speed Automated Operation

The fully automated nature of the machine allows for high-speed packaging, significantly increasing production capacity and reducing labor costs. This ensures a high output in a short amount of time, perfect for businesses with large-scale production requirements.

Durable, Secure Packaging

The shrink film tightly hugs the product, providing a tamper-evident and durable seal. This offers superior protection against external contaminants such as moisture, dust, and dirt, ensuring the product reaches customers in perfect condition.

Versatile Handling of Various Products

Whether it’s irregularly shaped items or multiple products packed together, the Shrink Wrapping Machine is capable of handling a wide range of product types, making it highly adaptable to different industries.

User-Friendly Interface

The shrink wrapping machine features an intuitive control panel with easy-to-understand functions, enabling operators to quickly learn how to use it. This reduces the need for extensive training and minimizes the chance of user error.

Improved Visual Appeal

The tight, flawless shrink film enhances the appearance of the product, creating a smooth and professional finish that attracts customers. This improved presentation helps boost the product's shelf appeal and marketability.

Energy-Saving Technology

The Shrink Wrapping Machine is designed to operate with minimal energy consumption, reducing operational costs while maintaining high performance. This energy efficiency makes it an excellent choice for businesses aiming to cut down on electricity costs.

Robust and Low Maintenance

Built with high-quality materials and advanced engineering, the machine is highly durable and requires minimal maintenance, resulting in fewer repairs and downtime. This ensures consistent performance and long-term reliability.

Model | BS-450 |

| Votalge | 110/220V 50-60Hz |

| Pump Power | 7.5kw |

| Shink Time | 0-10p/min |

| Weight | 220.5 lb 100 kgs |

| Certification | CE ISO |

MAXIMUM PACKAGE SIZE

| max width: | 17.7 inch(450mm) |

| max height: | 9.8 inch(250mm) |

QUARTZ TUBE HEATING

Quartz tube heating combined with strong wind circulation makes the heating chamber temperature more uniform, while saving energy and electricity

WIND CIRCULATION SYSTEM

Equipped with wind blade device, provide large wind power, so that the shrinkage furnace to form a good wind circulation system, so that the shrinkage effect is more uniform!

QUARTZ FAR-INFRARED TUBE

The quartz infrared tube heating method can continuously produce infrared radiation during operation, and the heating in the furnace is more uniform to achieve satisfactory shrinkage effect.

ADJUSTABLE TRANSMISSION SPEED

The appropriate speed can be adjusted according to the film type, thickness and package size

TURBOFAN

The turbine wind wheel is used in the furnace to heat the furnace evenly, and the temperature can also rise rapidly

MECHANICAL KNOB

Fine control of the furnace environment

HIGH TEMPERATURE PROOF DUST CLOTH

Use high quality materials

Keep the furnace temperature uniform

AIR SWITCH

Independent air switch is used to ensure safety and easy maintenance

BULK INLET

The material entrance adopts large size open design,

and the entrance adopts high temperature cloth as cover,

which makes the equipment safer during operation!

APPLICATION

OUT OF THE BOX

No installation required