Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Are you looking for a way to boost packaging efficiency and product protection? The demand for efficient packaging solutions is growing rapidly across industries. A double chamber vacuum packing machine could be the game-changer you need.

In this article, we’ll explore how these machines extend shelf life, protect products, and speed up packaging processes. You’ll also learn which industries, from food to medical packaging, can benefit from this technology.

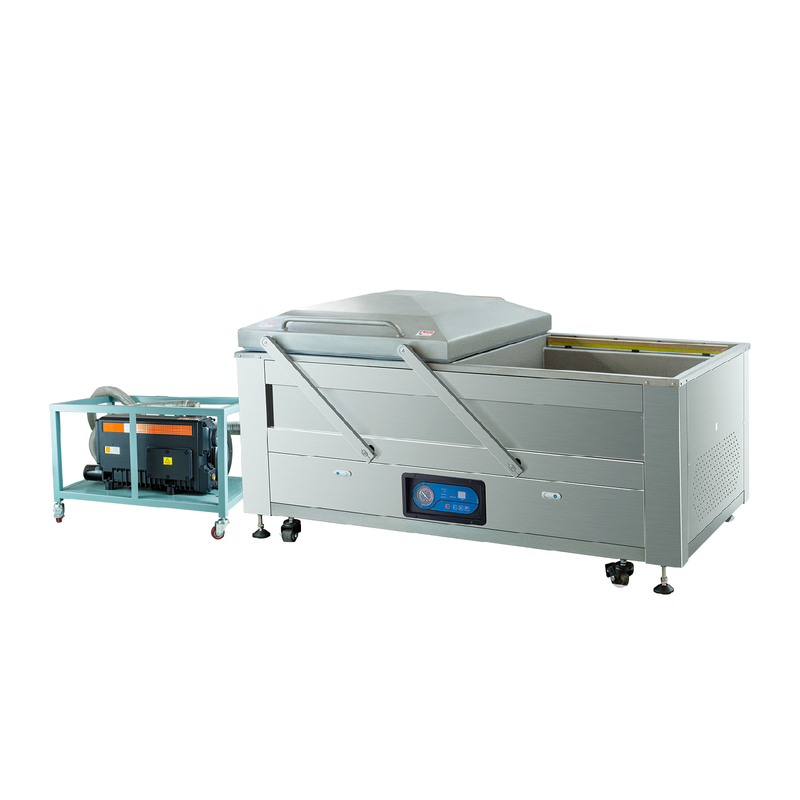

A double chamber vacuum packing machine is designed to streamline the packaging process. It uses a dual-chamber system, allowing for more efficient operations compared to single-chamber machines.

It’s a packaging device that uses two chambers. One chamber seals products while the other is loaded, making the process faster and more efficient.

The system works by alternating between chambers. While one chamber is vacuum-sealing products, the other chamber is ready for the next batch. This eliminates downtime and speeds up the entire process.

● One chamber seals, while the other is being loaded, ensuring continuous operation.

● No waiting time: A key benefit for high-volume production.

Vacuum sealing works by removing air from packaging. This process helps protect products from oxidation, which can degrade their quality. By creating an airtight seal, the vacuum helps to preserve the freshness of food and other items.

● Prevents oxidation, extending shelf life.

● Keeps items fresh, especially in food packaging.

Unlike single-chamber machines, double chamber vacuum sealers offer greater efficiency. While a single-chamber machine can only process one item at a time, a double chamber machine allows for continuous packaging.

● Double chamber machines handle larger volumes.

● Single chamber machines can be slower, leading to more downtime.

In short, the added dual chambers increase packaging speed and efficiency, making them ideal for businesses that need to package large quantities quickly.

Double chamber vacuum sealers are designed to enhance efficiency, durability, and ease of use in high-volume packaging. Here are the key features that make these machines stand out:

The dual-chamber system is a major selling point. It allows for continuous operation, which boosts productivity.

● Two chambers: One chamber seals while the other is loaded, ensuring no downtime between cycles.

● This process makes packaging faster, helping businesses increase throughput.

● Larger volumes: A double chamber machine handles more products at once compared to a single-chamber model.

By alternating between chambers, these machines are perfect for large-scale operations. They reduce wait time and keep the workflow moving.

A significant advantage of double chamber vacuum packing machines is their ability to seal a variety of products. Machines like the DZQ-1000/2SA FLAT come equipped with four 1000mm sealing bars, providing a wide sealing area.

● Versatile sealing: The large sealing area is ideal for different pouch sizes and product types.

● Examples: The DZQ-1000/2SA FLAT handles everything from delicate fruits to bulky meats.

● Whether it's seafood, medical supplies, or industrial items, these machines accommodate diverse packaging needs with ease.

One of the standout features is the customizable vacuum pumps. These pumps range from 100m³/h to 400m³/h, allowing businesses to choose the ideal capacity for their needs.

● Optimal vacuuming power: Larger pumps provide more suction, ensuring the best results for different product types.

● The right pump ensures fast, efficient vacuum sealing, reducing packaging cycle time.

● The DZQ-1000/2SA FLAT offers various pump capacities, ensuring flexibility in production.

Maintenance is simple, thanks to the machine's stainless steel construction. Stainless steel not only enhances durability but also maintains hygiene.

● Corrosion-resistant: Stainless steel resists rust, ensuring long-lasting performance in harsh environments.

● Flat design: The DZQ-1000/2SA FLAT model features a flat chamber that’s easier to clean than deeper models.

● Ergonomic design: The machine’s user-friendly interface makes operation simpler and more efficient.

These features work together to provide a packaging solution that’s both reliable and easy to maintain.

There are different models of double chamber vacuum packing machines, each offering unique features and benefits. Let's explore some of the most popular options and their applications:

The DZQ-1000/2SA FLAT is known for its high capacity and customization options.

● Key features: Four 1000mm sealing bars, a 10mm sealing width, and a customizable vacuum pump.

● Ideal applications: Perfect for packaging meat, seafood, and other food items. It works well for large items like sheep legs, pork, fish, and more.

● Customization: Users can choose from various pump sizes and chamber designs, making it adaptable to different needs.

This model is highly versatile and can handle a variety of products, making it ideal for high-volume operations in food packaging.

The DZQ-900/2SA model is designed for industries needing high-capacity packaging.

● Detailed features: Customizable pump options ranging from 100m³/h to 400m³/h, offering flexibility to match different vacuuming needs.

● Applications: It's ideal for food processing plants, central kitchens, and medical industries. It can also pack non-food items such as medical devices or hardware.

● High capacity: This model is widely used for packaging large volumes of products.

The DZQ-900/2SA excels in environments where high throughput is needed, providing reliable and efficient packaging.

The DZQ-850/2SE is tailored for businesses that require flexibility in both chamber design and pump capacity.

● Chamber design: This machine features a customizable chamber depth, allowing it to handle bulkier items, such as large cuts of meat or whole fish.

● Specialized industries: It is ideal for packaging items like large industrial equipment, hardware, and more.

● Pump capacity: Offers the ability to choose the right pump for your specific needs, making it adaptable for different product sizes and volumes.

The DZQ-850/2SE provides excellent flexibility for industries dealing with larger or bulkier products that need careful packaging.

Investing in a double chamber vacuum packing machine brings several advantages that can significantly improve packaging operations. Here's why it's a smart choice:

The dual-chamber design is a game-changer when it comes to efficiency.

● Reduces downtime: While one chamber seals, the other is loaded, eliminating waiting time.

● Faster processing: A double chamber vacuum packing machine increases the speed of the packaging process.

● Comparison: Compared to single-chamber machines, double chambers double the productivity, handling more items in less time.

This design boosts operational efficiency by ensuring continuous, uninterrupted packaging.

Double chamber vacuum sealers are incredibly versatile, able to handle a wide range of items across various industries.

● Food industry: Ideal for packaging meats, seafood, fruits, and more.

● Non-food applications: Suitable for medical devices, hardware, and other items that need protection.

● Adaptable: Whether it's delicate food or bulky industrial items, these machines can handle both with ease.

This versatility makes them a top choice for businesses dealing with different types of products.

One of the biggest benefits of vacuum sealing is the extended shelf life it provides.

● Prevents oxidation: Helps keep fatty foods like nuts and meats fresh by removing air.

● Inhibits mold and bacteria growth: Vacuum packaging prevents the growth of harmful microorganisms.

● Protects products: It also shields products from contaminants and moisture, ensuring they stay in good condition for longer.

By preserving freshness and preventing spoilage, vacuum sealing is a crucial tool for businesses that want to offer longer-lasting products.

Double chamber vacuum sealers are used in many industries, each benefiting from their efficiency and versatility. Let's dive into some of the most common applications:

Vacuum sealing is crucial for preserving the freshness of food items like meats, seafood, fruits, and vegetables.

● Longer shelf life: The double chamber vacuum packing machine removes air, preventing spoilage and extending freshness.

● Preserving quality and flavor: It keeps the flavor intact, ensuring food items taste fresh when opened later.

● Cooked food preservation: Vacuum sealing helps maintain the aroma, texture, and overall quality of cooked meals.

Whether it's raw or cooked food, vacuum packaging ensures it stays fresh longer, which is essential for the food industry.

Medical industries rely on vacuum sealing for the protection of sensitive equipment and supplies.

● Prevents contamination: Vacuum sealing ensures that medical equipment, pharmaceuticals, and lab samples remain free from contaminants.

● Maintains sterility: It helps keep items sterile, which is critical for safety and hygiene in medical environments.

In healthcare, where cleanliness and safety are paramount, a double chamber vacuum packing machine plays a crucial role in maintaining product integrity.

Vacuum packing isn’t just for food or medical products—it’s also essential in packaging tools and industrial items.

● Protects from dust and moisture: Vacuum sealing keeps equipment safe from environmental elements like moisture, dust, and dirt.

● Secure packaging: The strong, airtight seal ensures tools and other hardware are well-protected during storage and transportation.

For industries dealing with valuable or sensitive equipment, vacuum packing offers reliable protection against damage from the environment.

Choosing the right double chamber vacuum packing machine depends on several factors. Here’s what to consider before making your purchase:

The size and capacity of the vacuum chamber play a key role in how well the machine fits your needs.

● Choosing the right size: If you're packaging larger items, a machine with a bigger chamber depth, like the DZQ-850/2SE (350mm depth), is ideal.

● Customization: You may need a customizable chamber depth to accommodate specific products like bulkier meats or large industrial equipment.

Selecting the right chamber ensures your machine can handle your products without wasting time or energy.

The vacuum pump’s power is crucial to achieving the right vacuum level.

● Pump capacity: A higher pump capacity means stronger suction, making it ideal for packaging large volumes.

● For example, choosing between a 100m³/h or 400m³/h pump depends on the scale of your operation.

● The right pump ensures fast and efficient packaging without compromising quality.

The pump's power should align with your business's packaging needs to avoid underperforming or overworking the machine.

The sealing length and width determine how much you can package at once.

● Sealing length: The DZQ-1000/2SA offers a 1000mm sealing length, which allows businesses to seal larger items or multiple smaller items simultaneously.

● Sealing width: A 10mm sealing width ensures a secure and airtight seal, preventing air from entering the package and extending shelf life.

Consider your product size and packaging needs to determine the optimal sealing length for your business.

Investing in a durable machine reduces long-term costs and ensures smooth operations.

● Maintenance: Choose a vacuum sealer that is easy to clean and maintain. Machines made from stainless steel are durable and resistant to corrosion.

● Waterproof and hygiene: Stainless steel ensures the machine remains hygienic and resistant to moisture, which is especially important in food-related applications.

A durable, low-maintenance machine not only lasts longer but also helps maintain consistent performance over time.

When considering a double chamber vacuum packing machine, the initial cost is just one factor. Let’s look at the long-term savings and return on investment (ROI).

● Upfront cost vs long-term savings: While the initial cost might be higher than simpler machines, the savings over time are significant. With reduced product wastage and longer shelf life, businesses save money in the long run.

● Reduced wastage: A double chamber vacuum packing machine helps extend the shelf life of perishable items, which reduces spoilage and waste. This directly boosts profitability.

● Higher productivity: These machines increase packaging speed by allowing simultaneous loading and sealing. More items are packed in less time, leading to increased efficiency and reduced labor costs.

● ROI for high-volume businesses: For businesses that handle large volumes, the double chamber vacuum packing machine offers a fast return on investment. The increased packaging efficiency helps businesses handle more products, reducing operational costs.

In the long run, these machines lead to better cost management and enhanced profits, especially in industries that require high-volume packaging.

Like any machinery, a double chamber vacuum packing machine may face occasional issues. Here’s how to fix some common problems and keep your machine running smoothly.

One of the most common problems is weak seals, which can lead to air leaks.

● Causes: Worn-out sealing strips or a malfunctioning vacuum pump may be the culprits.

● Solutions:Inspect sealing strips for wear and replace if needed.

○ Check the vacuum pump for proper function. If it’s not creating enough pressure, it may need repairs or replacement.

● Prevention: Regularly clean the sealing bars and ensure they are properly aligned.

A secure seal is essential for product freshness, so address these issues as soon as they arise.

If your machine isn’t achieving the desired vacuum level, there are a few things to check.

● Common problems: Air leaks or a damaged vacuum pump can prevent proper vacuuming.

● Solutions:Check for air leaks around the chamber seals. Tighten or replace seals if necessary.

○ Inspect the vacuum pump for blockages or malfunctions. Replace the pump if it’s not operating at full capacity.

● Pump and chamber checks: Ensure the chamber is free of debris, and the pump is performing at optimal power.

Ensuring a proper vacuum is critical for preserving products and avoiding wasted packaging.

Electrical issues can sometimes cause performance problems.

● Common electrical issues: These might include faulty wiring or malfunctioning control boards.

● Solutions:Regularly inspect the electrical components for damage. If a problem is found, consult a technician for repairs.

○ Keep connections clean and secure to prevent electrical shorts.

● Maintenance tips:Schedule periodic maintenance checks to catch small problems before they become bigger issues.

○ Ensure all electrical components are free of moisture or corrosion.

Routine maintenance can prevent electrical issues and prolong the life of your double chamber vacuum packing machine.

Double chamber vacuum packing machines are essential for enhancing business efficiency, productivity, and product quality. Whether in food production, medical packaging, or hardware industries, these machines provide significant benefits. Investing in the right vacuum sealer can help businesses meet their specific packaging needs and improve their bottom line.