loading

| Availability: | |

|---|---|

| Quantity: | |

PFS-300I

DFPACK

Meat, Seafood, Cooked Food, Fruits and Vegetables, Baking, Granules, Liquids, Powders, Medical Equipment, Hardware

Pouch

Sealing

Low

Advantage

Durable Structure: The iron casing provides enhanced strength and durability, making the machine highly suitable for heavy-duty use and ensuring long-term reliable operation.

Manual Operation: The manual operation design offers precise control over the sealing process, allowing operators to easily adjust temperature and sealing time settings for different packaging materials.

Versatile Sealing Capabilities: Suitable for sealing a variety of materials, including plastic bags, aluminum foil pouches, and composite films. This versatility makes it a valuable tool for handling diverse packaging needs.

Compact and Space-Efficient: Despite its robust build, the machine is compact in size, making it suitable for small workspaces and ideal for small to medium-sized production areas.

Cost-Effective: Provides a high-quality sealing solution at a lower price compared to automated systems, making it a budget-friendly option with good cost efficiency.

| Model | PFS-300I |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 0.45kw |

| Sealing Length | 11.8 inch 300mm |

| Sealing Width | 0.1 inch 2mm |

| Weight | 8.8 lb 4kgs |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

CERTIFICATE

Global Distributor Program | 12+ International Exhibitions Annually

With 36+ years of vacuum packaging expertise, we showcase CE-certified, self-designed machinery at premier exhibitions including CANTON FAIR, INTERPACK, PROPAK, and SWOP.

Highlights

Global Support:Annual production capacity exceeding 2,000,000 units. Exported to 100+ countries.

Tailored Solutions:Our team delivers professional vacuum packaging solutions leveraging extensive experience, backed by reliable after-sales service.

Clients as Partners:We treat every customer as a valued partner, prioritizing their needs and concerns to ensure tangible benefits.

| Model | PFS-300(5mm) |

| Max package width | 11.0 in(280mm) |

| Sealing width | 0.2 in(5mm) |

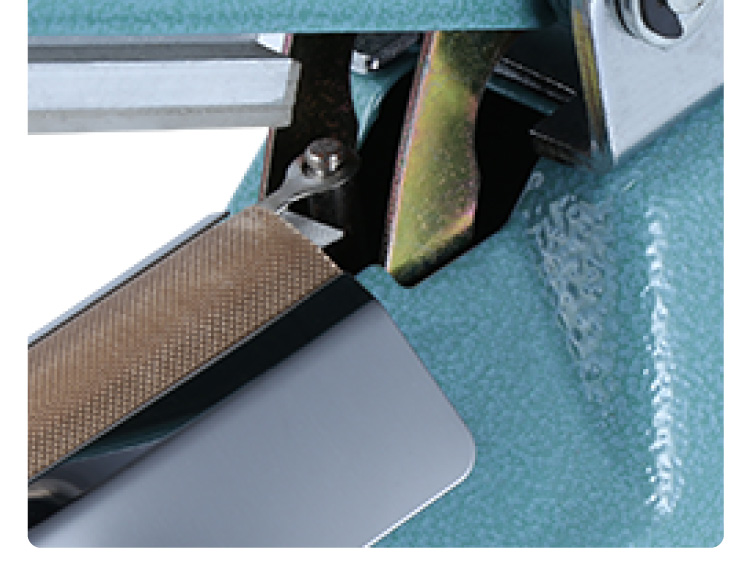

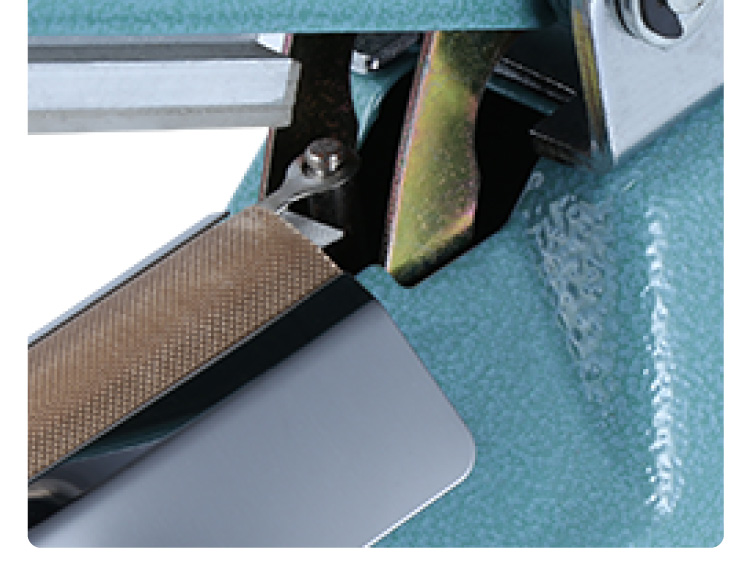

AUTOMATIC COVER OPENING

Smooth work procedures are more comfortable

SILICONE SEAL STRIP

The silicone strip is soft and elastic, so that the sealing force is more uniform, and the sealing effect is better

THIN PANEL

Mechanical knob design, intuitive interface simple operation, easy to use

EASY TO REPLACEMENT

A Phillips screwdriver to complete the replacement of accessories

THICKENED METAL CONNECTORS

Strong fixed, handle left and right do not run off, the machine work more stable

PURE COPPER TRANSFORMER

The pure copper transformer has the advantages of durability, stability and strong power, and can work continuously for a long time

| Copper wire transformer | What are the differences between copper and aluminum transformers | Aluminum wire transformer |

| strong | Electrical conductivity | weak |

| high | Fusing point | low |

| strong | Short-circuit resistance | weak |

| higher | Mechanical strength | lower |

| low | Electrical resistivity | Easy to increase |

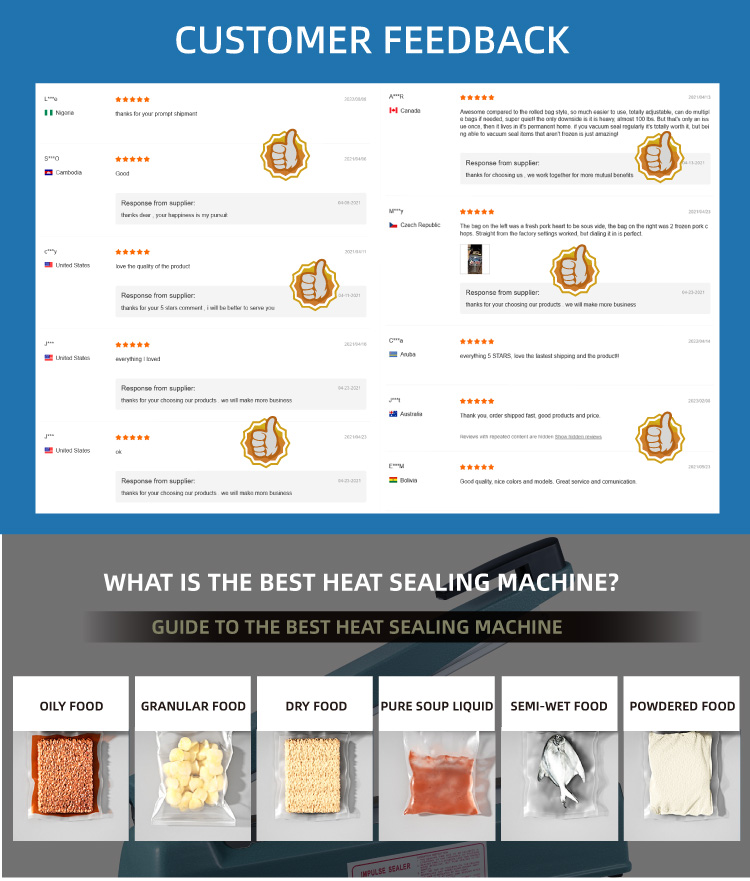

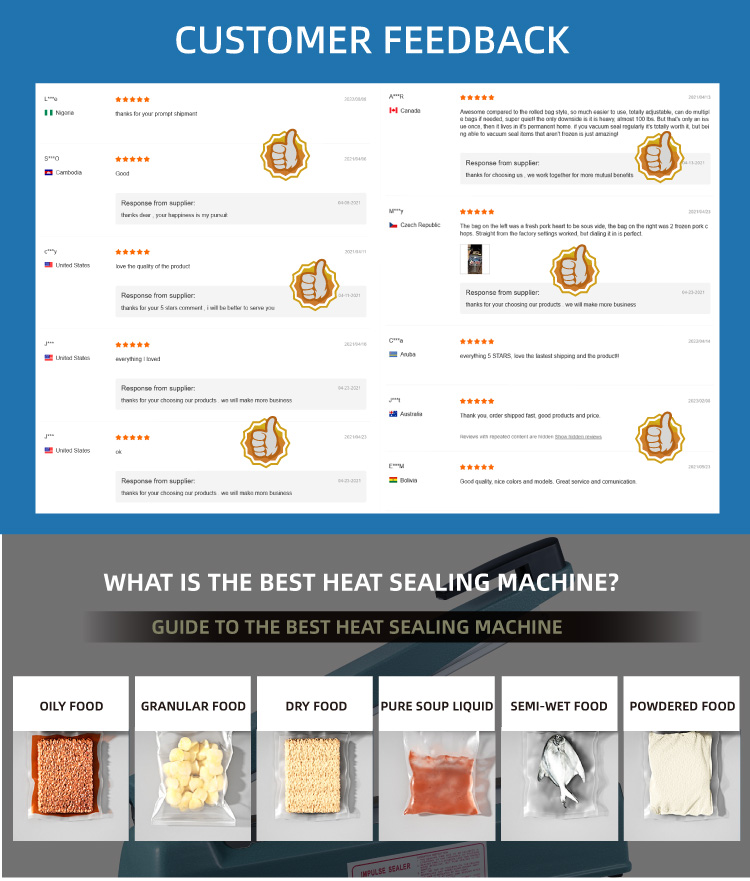

APPLICATION

The PFS-300I hand-press sealing machine is suitable for sealing various heat-sealed packaging bags. The packaged products can be isolated, mold-proof, insect-proof, moisture-proof and can be kept fresh for a long time.

PACKAGING & SHIPPING

Your machine will be delivered by sea, air or express according to your needs.Before packaging, the goods are first wrapped with protective film to prevent scratches and corrosion, and then placed in wooden boxes for shipment.

OUT OF THE BOX

No installation required

So far, the factory covers an area of 26,800 square meters and has more than 300 workers, among whom there are 40 engineering and technical personnel. As a national high-tech enterprise, we have a mature management system covering R&D, production, sales, quality inspection and after-sales service. After 36 years of efforts, our company's annual production capacity is currently approximately 2,000,000 sets, and our products are exported to over 100 countries.

FAQ

Advantage

Durable Structure: The iron casing provides enhanced strength and durability, making the machine highly suitable for heavy-duty use and ensuring long-term reliable operation.

Manual Operation: The manual operation design offers precise control over the sealing process, allowing operators to easily adjust temperature and sealing time settings for different packaging materials.

Versatile Sealing Capabilities: Suitable for sealing a variety of materials, including plastic bags, aluminum foil pouches, and composite films. This versatility makes it a valuable tool for handling diverse packaging needs.

Compact and Space-Efficient: Despite its robust build, the machine is compact in size, making it suitable for small workspaces and ideal for small to medium-sized production areas.

Cost-Effective: Provides a high-quality sealing solution at a lower price compared to automated systems, making it a budget-friendly option with good cost efficiency.

| Model | PFS-300I |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 0.45kw |

| Sealing Length | 11.8 inch 300mm |

| Sealing Width | 0.1 inch 2mm |

| Weight | 8.8 lb 4kgs |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

CERTIFICATE

Global Distributor Program | 12+ International Exhibitions Annually

With 36+ years of vacuum packaging expertise, we showcase CE-certified, self-designed machinery at premier exhibitions including CANTON FAIR, INTERPACK, PROPAK, and SWOP.

Highlights

Global Support:Annual production capacity exceeding 2,000,000 units. Exported to 100+ countries.

Tailored Solutions:Our team delivers professional vacuum packaging solutions leveraging extensive experience, backed by reliable after-sales service.

Clients as Partners:We treat every customer as a valued partner, prioritizing their needs and concerns to ensure tangible benefits.

| Model | PFS-300(5mm) |

| Max package width | 11.0 in(280mm) |

| Sealing width | 0.2 in(5mm) |

AUTOMATIC COVER OPENING

Smooth work procedures are more comfortable

SILICONE SEAL STRIP

The silicone strip is soft and elastic, so that the sealing force is more uniform, and the sealing effect is better

THIN PANEL

Mechanical knob design, intuitive interface simple operation, easy to use

EASY TO REPLACEMENT

A Phillips screwdriver to complete the replacement of accessories

THICKENED METAL CONNECTORS

Strong fixed, handle left and right do not run off, the machine work more stable

PURE COPPER TRANSFORMER

The pure copper transformer has the advantages of durability, stability and strong power, and can work continuously for a long time

| Copper wire transformer | What are the differences between copper and aluminum transformers | Aluminum wire transformer |

| strong | Electrical conductivity | weak |

| high | Fusing point | low |

| strong | Short-circuit resistance | weak |

| higher | Mechanical strength | lower |

| low | Electrical resistivity | Easy to increase |

APPLICATION

The PFS-300I hand-press sealing machine is suitable for sealing various heat-sealed packaging bags. The packaged products can be isolated, mold-proof, insect-proof, moisture-proof and can be kept fresh for a long time.

PACKAGING & SHIPPING

Your machine will be delivered by sea, air or express according to your needs.Before packaging, the goods are first wrapped with protective film to prevent scratches and corrosion, and then placed in wooden boxes for shipment.

OUT OF THE BOX

No installation required

So far, the factory covers an area of 26,800 square meters and has more than 300 workers, among whom there are 40 engineering and technical personnel. As a national high-tech enterprise, we have a mature management system covering R&D, production, sales, quality inspection and after-sales service. After 36 years of efforts, our company's annual production capacity is currently approximately 2,000,000 sets, and our products are exported to over 100 countries.

FAQ