Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

You see vacuum packaging machines in action across many industries today, thanks to their efficiency and versatility. These machines remove air from packages and seal them tightly, which preserves freshness and protects contents during shipping. The global market for vacuum packaging machines stands at USD 22.16 billion in 2024, with projections reaching USD 32.86 billion by 2032.

Common uses include:

Food and beverage preservation

Pharmaceuticals and medical supplies

Consumer goods and electronics

With a vacuum packaging machine, you extend shelf life, prevent spoilage, and ensure safe storage for everything from meats and cheeses to delicate electronics.

Vacuum packaging extends the shelf life of food by removing air, slowing down spoilage, and keeping items fresh for longer periods.

Using a vacuum packaging machine enhances operational efficiency, reduces waste, and saves money on labor and materials.

These machines are versatile and can be used across various industries, including food, pharmaceuticals, and electronics, ensuring product safety and quality.

Vacuum packaging optimizes storage space by shrinking package sizes, which can lead to significant savings in warehouse costs.

Maintaining hygiene and safety standards is easier with vacuum packaging, as it prevents contamination and ensures compliance with industry regulations.

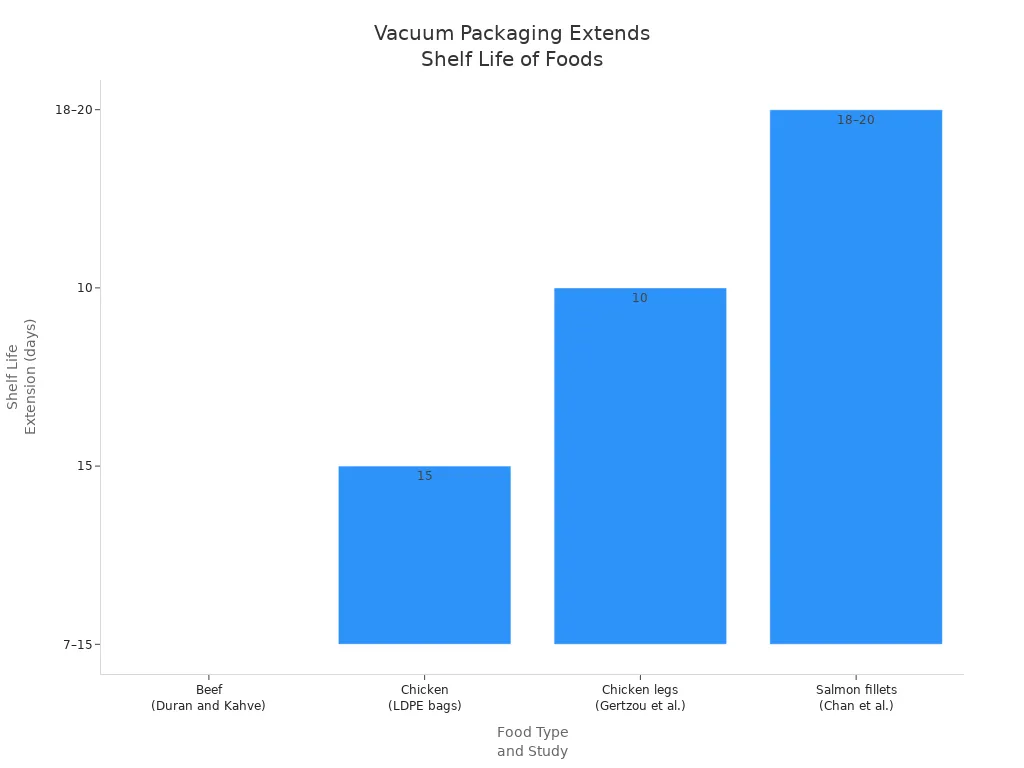

You rely on a vacuum packaging machine to keep food fresh for longer. By removing air, you slow down oxidation and stop bacteria from growing. This process helps preserve food like beef, chicken, and fish, making prepping easier and reducing spoilage. Scientific studies show that vacuum packing food can extend shelf life by days or even weeks. For example, beef lasts 7–15 days, chicken up to 15 days, and salmon fillets up to 20 days when vacuum sealed.

| Study | Food Type | Shelf Life Extension | Notes |

|---|---|---|---|

| Duran and Kahve | Beef | 7–15 days | Prevents growth of bacteria and preserves natural freshness |

| Low-density bags | Chicken | 15 days | Vacuum packing food increases shelf life |

| Gertzou et al. | Chicken legs | 10 days | Polyamine/polyethylene bags used |

| Chan et al. | Salmon fillets | 18–20 days | 1.5 times longer than non-packaged fillets |

Vacuum packaging preserves food quality, keeps food safe, and protects food from freezer burn. You can keep it fresh for longer and enjoy vacuum sealed food with natural freshness.

A vacuum packaging machine streamlines prepping and packaging. Automated systems reduce labor and material costs, saving money for your business. You benefit from energy-efficient machines and reduced spoilage, which means less waste and more savings.

| Evidence Type | Description |

|---|---|

| Energy Efficiency | Machines consume less electricity, lowering utility bills |

| Automation | Streamlined workflows and reduced labor costs |

| Material Optimization | Efficient design minimizes waste and lowers costs |

| Reduced Spoilage | Extended shelf life leads to less waste and more savings |

Vacuum sealing foods increases productivity and durability, making your operations smoother.

Vacuum packaging machines serve many sectors. You use them to vacuum pack food, preserve medical supplies, and protect electronics. In medical settings, vacuum sealing keeps items sterile and safe. In explosives, vacuum packaging prevents oxidation and moisture damage.

| Industry | Specific Use Case |

|---|---|

| Medical | Vacuum sealing keeps items sanitary and maintains sterility until opened |

| Explosives | Prevents moisture and oxidation, ensuring stability and safety |

Vacuum packaging adapts to prepping needs, offering durability and protection for a wide range of products.

Vacuum packaging reduces spoilage and helps you optimize storage space. By removing air, you shrink package size and decrease warehouse needs by up to 30%. Businesses report thousands of dollars saved annually due to less waste. Vacuum packing food also makes logistics more efficient, as products stay fresh and require less refrigeration during transport.

Tip: Vacuum packaging helps you preserve food and optimize prepping space, making storage and transportation easier.

You meet strict hygiene and safety standards with vacuum packaging machines. Vacuum sealing removes air and fluids, enhancing shelf life and preventing leakage. In food and medical industries, calibration and validation ensure quality. Specialized cleaning solutions, such as UV disinfection, eliminate bacteria and viruses, keeping your products safe.

| Industry | Improvement Details | Results |

|---|---|---|

| Pharmaceutical | Increased leak detection sensitivity, reduced defect rate | 72% decrease in product recalls over six months |

| Food Manufacturing | Improved shelf life, detected leaks, reduced spoilage complaints | 56% reduction in customer complaints related to spoilage |

| Consumer Goods Packaging | Reduced leaks, fewer product returns | Saved $1.2 million annually in recall-related costs |

Vacuum packaging machines protect your products, preserve their quality, and ensure compliance with industry standards.

When you compare entry-level vacuum packaging machines to industrial models, you notice clear differences in cost, capacity, and maintenance. Entry-level machines usually cost less than $10,000. These models work well for small businesses or startups that need to package food in lower volumes. Industrial machines, on the other hand, can exceed $100,000. You get advanced features, higher speed, and larger capacity with these systems.

Entry-level machines suit small-scale food operations and home use.

Industrial machines handle high-volume food processing and offer customizable options.

Maintenance costs for industrial machines stay lower because they have fewer moving parts and better design.

You experience less downtime and fewer repairs with industrial models, which lowers your total cost of ownership.

Industrial systems also reduce repair costs due to less wear and tear.

Note: If you run a large food production facility, investing in an industrial vacuum packaging machine can save you money over time by reducing maintenance and repair expenses.

Vacuum packaging machines adapt to the unique needs of different industries. You see these machines in food processing, pharmaceuticals, and electronics manufacturing. Each sector has its own requirements for packaging safety and efficiency.

| Industry | Common Requirements |

|---|---|

| Food Industry | Preservation of perishable foods, prevention of freezer burn, enhancement of food safety. |

| Medical and Pharmaceutical Sector | Ensuring sterility of medical devices and pharmaceutical products. |

| Electronics and Manufacturing | Safeguarding sensitive electronic components and preventing moisture damage. |

Manufacturers tailor machines to meet these needs. You benefit from features like adjustable settings for different packaging materials and modified atmosphere packaging. Many companies now focus on sustainability, using eco-friendly materials and energy-saving designs. Machines for the food industry often include easy-to-clean surfaces and sanitation systems to comply with food safety regulations.

You extend product shelf life and prevent freezer burn.

Machines help maintain flavor and nutritional value in food.

Enhanced product safety protects your brand reputation.

Customization options allow you to match machine features to your specific food products.

Tip: When choosing a vacuum packaging machine, consider your supplier’s production capacity, the investment potential of the machine, and the quality of materials used.

Selecting the right vacuum packaging machine for your business requires careful evaluation of your production needs, product types, and long-term goals. You want a solution that matches your daily workflow and supports the quality standards your customers expect.

Start by assessing your packaging volume and the types of food or goods you handle. If you process high volumes of food, you need a machine with greater capacity and speed. For smaller batches, a compact model may suit your space and budget. Consider whether you package moist foods, dry goods, or delicate items, as this affects the required vacuum strength and sealing method.

Tip: Always match the machine’s capabilities to your most demanding food products to avoid bottlenecks.

Here is a comparison of factors for small businesses and large-scale operations:

| Factor | Small Businesses | Large-Scale Operations |

|---|---|---|

| Vacuum Strength | Higher strength for moisture-rich food | High capacity and efficiency |

| Sealing Method | External or chamber technology | Advanced sealing for bulk food |

| Bag Compatibility | Cost-effective vacuum rolls | Specialized bags for large volumes |

| Ease of Use | User-friendly controls | Complex systems for automation |

| Maintenance | Easy cleaning and reduced downtime | Regular maintenance for high-volume food |

| Additional Functions | Sealing containers or jars | Versatile packaging solutions |

| Size and Portability | Compact and portable | Stationary, requires dedicated space |

When you compare technical specifications, focus on vacuum degree, sealing strength, and pump speed. Reliable machines maintain consistent performance, which is vital for preserving food quality. You should also consider ease of use and serviceability, as these features reduce reliance on technical support and minimize downtime.

Key considerations include:

Packaging volume determines machine capacity and speed.

Product type affects compatibility and performance.

Budgeting involves both initial investment and ongoing costs like maintenance and energy.

Production volume guides your choice between manual, semi-automatic, or fully automated systems.

Evaluate long-term value, not just upfront price.

Certifications matter for food safety and legal compliance. Look for machines with ISO 9001, CE marking, and HACCP. Compliance with FDA and USDA standards is essential for food import and export. Certified machines assure your customers that their food is packaged safely and meets regulatory requirements.

Vacuum packaging machines deliver clear advantages for your business or home. You improve efficiency, extend the shelf life of food, and reduce waste. The technology keeps food safe, prevents freezer burn, and supports organized storage. Many industries rely on vacuum packaging to maintain product quality and meet safety standards.

| Benefit | Description |

|---|---|

| Cost Savings | Lower waste and optimize storage for food and goods |

| Food Safety | Enhance protection and reduce contamination risks |

| Versatility | Adapt to various industries and packaging needs |

Explore different vacuum packaging machine models to find the best fit for your food preservation and operational goals.

You can vacuum package a wide range of products. These include fresh foods, cooked meals, medical supplies, electronics, and even textiles. The machine adapts to different shapes and sizes, making it suitable for many industries.

Vacuum packaging removes air from the package. This process slows down oxidation and prevents bacteria growth. Your products stay fresh longer, and you reduce spoilage.

Most modern vacuum packaging machines feature user-friendly controls. You can set parameters with a touchscreen or simple buttons. Many models offer automatic modes for quick and efficient operation.

Yes, you can vacuum package liquids and moist foods. Some machines include special settings for wet items. You should use appropriate bags and monitor the sealing process to prevent leaks.

You should clean the chamber and sealing bar regularly. Check for worn seals and replace them as needed. Follow the manufacturer's guidelines for routine maintenance to ensure reliable performance.