Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

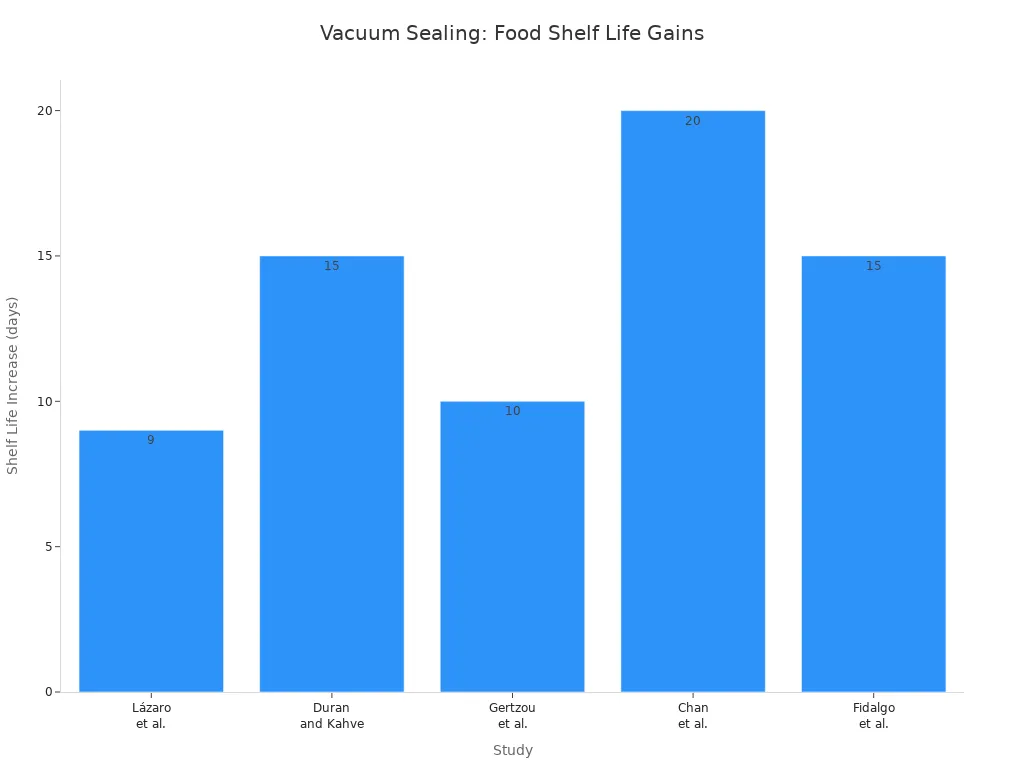

You see the effects of food waste every day. Households discard over 20% of food purchased, with fresh food losses reaching 37.48 kg per person each year. Vacuum packaging machine technology changes this by enhancing preservation and minimizing spoilage. Scientific studies reveal vacuum sealing can extend shelf life for salmon fillets up to 20 days and beef up to 15 days, far outperforming traditional storage.

| Food Type | Waste per Household per Person (kg/year) |

|---|---|

| Fresh Food | 37.48 |

| Frozen Food | 6.46 |

| Percentage of Food Waste | 20% or more of food purchased |

A vacuum packaging machine is a specialized device that helps you preserve food and other products by removing air from the packaging. You use this machine to create an airtight seal, which protects contents from spoilage and extends shelf life. The main purpose of vacuum packing is to keep food fresh, prevent contamination, and maintain quality for longer periods. You can rely on this technology in both home kitchens and commercial settings, where food safety and efficiency matter most.

You will find several types of vacuum packaging machines designed for different needs.

Chamber Vacuum Packaging Machine: You place the product inside a chamber, and the machine removes air before sealing. This type suits bulk packaging and commercial use.

External Vacuum Packaging Machine: You seal bags outside the machine, making it ideal for home use or small businesses.

Single Chamber, Dual Chamber, and Continuous Models: You select the model based on your production volume and product size. Dual chamber and continuous models boost efficiency for large-scale operations.

Tip: Choose a vacuum packaging machine that matches your product size and daily output for best results.

You operate a vacuum packaging machine by placing your product in a special bag or container. The machine uses a vacuum pump to remove air, then seals the package tightly. This process reduces oxygen, slows microbial growth, and prevents oxidation.

Here is a quick overview of the main components and their functions:

| Component | Function |

|---|---|

| Main Frame | Provides the main structure made of durable stainless steel for stable performance. |

| Control Board | Allows control of temperature, conveyor belts, sealing nozzle, and emergency stop. |

| Vacuum Room | The area where the container is placed for processing during the vacuum packaging. |

| Vacuum Pump | Reduces oxygen levels inside the container, ensuring product longevity. |

| Universal Caster | Enables easy movement of the machine with 360-degree rotation. |

| Sealing Frame | Joins the sides of plastic film through a heated seal bar, crucial for sealing packages. |

You benefit from vacuum packing by keeping food fresher, reducing waste, and saving money over time.

You face constant challenges with food spoilage. Microorganisms such as bacteria, mold, and yeast thrive when oxygen is present. When you use vacuum-sealed food products, you remove oxygen from the packaging. This process creates an anaerobic environment that inhibits the growth of spoilage organisms. In the meat industry, vacuum packaging limits oxygen availability, which slows down oxidative degradation and keeps food safe. You can rely on this method to extend the expiry of your food and maintain its quality for longer periods. By reducing oxygen, you maximize shelf life and protect your investment.

Oxidation causes food to lose flavor, color, and nutrients. You can prevent oxidation by using vacuum-sealed pouches. Research shows that vacuum packaging delays lipid oxidation in fish and ground beef.

Packaging materials that limit oxygen transmission reduce aerobic microbial growth and extend the shelf life of previously frozen beef steaks.

Vacuum-sealed food products show lower levels of malonaldehyde, a marker for oxidation, during storage.

You notice increased shelf life and better taste in vacuum-sealed food products because oxidation is minimized.

Moisture loss leads to dry, unappealing food. You can preserve moisture by using vacuum-sealed pouches. Laboratory studies confirm that vacuum-sealed food products retain moisture and freshness.

| Study | Findings | Duration of Shelf Life Increase |

|---|---|---|

| Moradinezhad & Dorostkar (2021) | Decreased weight loss and browning index in fresh produce | 1-3 days for strawberries |

| Odriozola-Serrano et al. (2009) | Maintained quality (phenolic and carotenoid content) and vitamin C | Up to 21 days for tomatoes at 4°C |

You extend the expiry of your food and keep it appealing for longer periods.

Freezer burn ruins the texture and flavor of food. You can prevent freezer burn by using vacuum-sealed food products.

Vacuum sealing creates an oxygen-free environment that minimizes exposure to cold, dry air. This method prevents ice crystal formation, which leads to dehydration and loss of flavor. You extend the expiry of your food and enjoy better taste and texture. Vacuum-sealed food products last longer and maintain their quality, reducing spoilage and waste.

You want your food to taste as fresh as possible, even after days or weeks in storage. Vacuum packaging for food preservation helps you achieve this goal. By removing air, you stop bacteria and mold from growing. This method keeps your food safe and tasty. You also protect the nutritional value and texture of your meals. When you use vacuum packaging, you can expect your food to stay fresh three to five times longer than with regular storage. For example, vacuum packed food like meats can last up to three years in the freezer, while dry goods such as rice can remain good for up to two years.

Maintains the edibility of food by preventing bacterial growth

Preserves the taste and nutritional properties

Reduces food waste by extending shelf life

Vacuum packaging for food preservation creates an oxygen-free environment. You keep your food tasting great and waste less food.

Freezer burn and dehydration ruin the quality of frozen food. You can avoid these problems with vacuum packaging. When you remove air from the package, you stop oxidative reactions that cause food to lose flavor and texture. The absence of oxygen also helps preserve the quality of your food.

Vacuum packaging removes oxygen from the food packaging environment

This process helps to maintain food quality and extends shelf life

It specifically reduces dehydration and freezer burn

You protect your vacuum packed food from ice crystals and dryness. Your meals stay moist and delicious, even after long periods in the freezer.

Vacuum packing food preservation lets you keep your food fresh for longer. Studies show that 78% of consumers notice that vacuum packaging helps maintain food freshness. Many people prefer air-tight packaging for items like salmon because it keeps them fresher. You can reduce food waste and food wastage in your home or business.

76% of Canadian consumers know about vacuum packaging and its benefits

Participants in studies significantly preferred vacuum packed food for freshness

You can reduce food wastage and save money by keeping food fresh longer

When you use vacuum sealing preserve food, you help reduce food waste and enjoy better meals. Vacuum sealing food preservation supports your efforts to waste less and enjoy more.

You gain a significant advantage when you use vacuum packaging machines with customizable chambers. These machines let you adjust vacuum settings and sealing parameters to fit different food types and packaging materials. You can seal food products ranging from delicate vegetables to robust cuts of meat. This flexibility ensures that each item receives the optimal preservation environment.

| Feature | Benefit |

|---|---|

| Adjustable vacuum settings | Precise control for different food types, enhancing preservation. |

| Custom sealing parameters | Optimal sealing for various packaging materials, reducing waste. |

Tip: Chamber vacuum sealers create an oxygen-free environment, which halts spoilage bacteria and keeps your products fresher for longer.

You often need to protect fragile foods during packaging. Soft Air Technology provides a gentle vacuum process that prevents crushing or damaging delicate items like bread, herbs, or soft cheeses. The machine gradually releases air back into the chamber, allowing the packaging to conform closely to the product without causing harm. This feature helps you maintain the original shape and texture of sensitive foods.

Prevents crushing of delicate products

Maintains product appearance and quality

Ideal for bakery goods, leafy greens, and soft cheeses

You can further extend shelf life by using nitrogen flushing. This method replaces oxygen in the package with nitrogen gas, which delays spoilage and oxidation. Nitrogen flushing also inhibits the growth of microorganisms that require oxygen, helping you keep food fresh and safe.

| Benefit | Description |

|---|---|

| Oxygen Displacement | Delays spoilage caused by oxidation. |

| Microbial Growth Inhibition | Prevents the growth of microorganisms that damage food. |

| Package Integrity | Maintains conformity of packaged products during shipping. |

| Shelf Life Extension | Increases shelf life and reduces food loss. |

Note: Nitrogen is a safe, affordable packaging gas that helps maintain product quality and package integrity during transport.

You can optimize the pickling process with specialized vacuum packaging modes. These settings help you preserve marinated meats and sausages by ensuring the brine or marinade remains evenly distributed. The vacuum process enhances flavor absorption and keeps the product moist. You achieve consistent results and extend the shelf life of pickled foods.

Ensures even marinade distribution

Enhances flavor and moisture retention

Ideal for marinated meats, sausages, and pickled vegetables

When you operate in a commercial environment, efficiency becomes your top priority. Vacuum packaging machines deliver measurable improvements across multiple industries, including food processing, pharmaceuticals, and electronics. You can streamline your workflow, reduce waste, and boost profitability with the right equipment.

The demand for commercial vacuum packaging continues to rise. Businesses like yours seek better food preservation and longer shelf life for products. You benefit from automation and technological advancements that make packaging faster and more reliable. As a result, you can handle higher volumes without sacrificing quality.

Consider the following key benefits that vacuum packaging machines bring to commercial operations:

| Benefit | Description |

|---|---|

| Cost Efficiency | Extends shelf life, reduces waste, and saves money on discarded products. |

| Minimized Spoilage | Helps minimize spoilage during transportation and storage. |

| Lower Operational Costs | Directly translates to higher profitability for food businesses. |

You see these advantages in action every day. Vacuum sealers keep perishable items fresh up to five times longer than traditional storage methods. By removing air, you slow oxidation and stop the growth of mold and bacteria. This means your products stay safe and appealing for longer periods.

Note: Vacuum packaging machines outperform alternatives like ziplock bags or containers. These older methods allow air to seep in, leading to faster spoilage and higher waste.

You also gain the ability to buy in bulk, which lowers your purchasing costs. Over time, the initial investment in a vacuum packaging machine pays off through reduced food waste and improved operational efficiency. You help conserve resources by minimizing food loss, which supports both your bottom line and environmental goals.

The market for commercial vacuum packaging machines grows each year.

You benefit from expanding applications in food, pharmaceuticals, and electronics.

Automation and innovation drive even greater efficiency in your business.

With a vacuum packaging machine, you position your business for long-term success and sustainability.

You want to maximize your investment in food preservation. Vacuum packaging machines help you save money by reducing food waste and spoilage. Unlike modified atmosphere packaging, you do not need expensive gas cylinders or specialized films. You use standard packaging materials, which lowers your costs by up to 30%. Automatic operation streamlines your workflow, so you spend less time and labor on packaging. When you buy in bulk, you store food safely for longer periods, which further reduces your expenses.

Vacuum sealers keep food fresh up to five times longer than traditional storage.

You minimize the need for frequent grocery trips and lower your overall food budget.

Businesses benefit from fewer discarded products and higher profitability.

Vacuum packaging machines adapt to a wide range of products and industries. You can preserve meats, cheeses, and vegetables, but you also protect electronics, pharmaceuticals, and important documents.

Vacuum sealers are great for more than just food. They can also protect important documents, photos, and electronics from damage.

You select from customizable chamber sizes and sealing modes to fit your needs. Machines with gas injection options extend shelf life and provide cushion protection for delicate items.

| Industry | Application Description |

|---|---|

| Food | Vacuum skin packaging enhances food safety and market reach through advanced techniques. |

| Electronics | Protects components from moisture and oxidation, ensuring longevity. |

| Pharmaceuticals | Maintains sterility and efficacy of medical supplies, crucial for health standards. |

| Non-food items | Originally designed for hardware, now used for various sensitive items. |

High-barrier films and advanced sealing techniques improve product preservation.

You enjoy flexibility in packaging sensitive or irregularly shaped items.

You notice that vacuum packaging delivers fresher, tastier food. Airtight seals slow oxidation, so you maintain flavor and texture.

Vacuum sealers outperform ziplock bags and containers in preserving marinated meats, ensuring better flavor and moisture retention.

Vacuum packaging extends shelf life by removing air, which slows the growth of bacteria and mold.

Consumers prefer vacuum-sealed products for home food preservation and trust the visible freshness.

Manufacturers meet international standards and consumer expectations by using advanced vacuum packing machines. You benefit from reliable packaging that keeps food safe during long-distance transport. The popularity of vacuum packaging continues to grow as more people recognize its advantages over traditional methods.

You can choose between portable and industrial vacuum packaging machines based on your needs. Portable models give you flexibility and easy transport. You can use them in kitchens, small businesses, or even at events. These machines deliver strong sealing performance for smaller tasks and fit well in limited spaces.

Industrial models work best for large-scale operations. You rely on them for continuous use in factories or food processing plants. They feature specialized filters and robust construction, which help you handle heavy-duty packaging and maintain hygiene standards.

Portable machines offer convenience and mobility.

Industrial machines support high-volume, nonstop packaging.

Both types ensure efficient sealing and help prevent contamination.

Modern vacuum packaging machines help you meet sustainability goals. Manufacturers now design machines that reduce single-use plastics and support eco-friendly packaging. You can select biodegradable, compostable, or recyclable films for your products. Many machines use energy-efficient motors and modular components to lower environmental impact.

Machines compatible with biodegradable and recyclable films.

Energy-saving features reduce electricity use.

Reusable packaging options cut down on plastic waste.

Extended shelf life means less food and packaging waste.

By keeping food fresh longer, you help reduce waste and conserve resources used in food production.

Smart technology transforms how you preserve food. New machines include sensors that monitor temperature and humidity, which helps you maintain product quality. AI-powered systems let you track packaging conditions in real time. This technology improves shelf life and reduces waste by adjusting settings automatically.

| Feature | Benefit |

|---|---|

| Sensors | Monitor storage conditions |

| AI Integration | Real-time adjustments for best results |

| Data Tracking | Ensures consistent product quality |

You gain better control over food safety and freshness with these smart features.

You see vacuum packaging machines everywhere in the food industry. These machines help you store food for longer periods and maintain freshness. You use them to prevent freezer burn and reduce food waste. You also find that vacuum packaging makes food easier to carry and store, saving space in your kitchen or warehouse. You lower costs and improve work efficiency when you rely on vacuum packaging for food products.

You extend the shelf life of food, including meats, seafood, and ready-to-eat meals.

You maintain food quality by removing air from packaging.

You reduce food waste by preventing spoilage.

You package cheese and dairy products to keep them fresh.

You use vacuum skin packaging to enhance the retail display of food.

Vacuum packaging lets you keep food safe and appealing for longer. You protect food from air, moisture, and contaminants, which helps you deliver better products to your customers.

You rely on vacuum packaging for fresh food, frozen food, and processed food. You see its benefits in restaurants, supermarkets, and food processing plants. You use vacuum packaging to preserve food flavor and texture, making it a vital part of your daily operations.

You find vacuum packaging machines useful in many industries outside of food. You use them to protect products from dirt, moisture, and pests. You also rely on vacuum packaging for compact storage and safe transport.

| Non-Food Products | Benefits of Vacuum Packaging |

|---|---|

| Sneakers | Free from dirt, moisture, and dust |

| Ink cartridges | Compact storage and transport |

| Medical products | Maintenance of quality and life span |

| Machine components | Protection against pests and reduced waste |

You use vacuum packaging to extend the life of medical products and keep machine components safe. You also store sneakers and ink cartridges more efficiently. You see how vacuum packaging helps you maintain product quality and reduce waste in many fields.

Vacuum packaging gives you reliable protection for sensitive items. You keep products in top condition, whether you work in healthcare, manufacturing, or retail.

You discover that vacuum packaging machines offer solutions for food and non-food products alike. You improve storage, safety, and efficiency across your business.

You want to maximize the shelf life of your food and maintain its quality. Following best practices with your vacuum packaging machine helps you achieve these goals. Start by preparing your food properly. Trim and portion meats before sealing. This step ensures even preservation and makes storage easier. For liquids, freeze them first to prevent spills during the vacuum process.

When you store food, choose the right environment. Place vacuum-sealed food in cool, dark locations to minimize exposure to heat and light. Use opaque containers to protect food from light damage. Rotate your food stores regularly to maintain temperature stability and freshness.

Cleaning your vacuum packaging machine after each use keeps your food safe and extends the life of your equipment. Hygiene is essential for preventing contamination. Always use airtight containers and consider adding oxygen absorbers for dry goods like grains, nuts, and dried fruits. Vacuum sealing helps prevent odor absorption, so your food stays fresh longer.

Here are some practical tips for how to vacuum pack food effectively:

Use vacuum sealing for cheeses, deli meats, and vegetables in the refrigerator.

Vacuum-seal dry goods for pantry storage.

Store food in low humidity areas to reduce moisture exposure.

Monitor vacuum quality to prevent spoilage.

Avoid using substandard machines to minimize technical issues.

Tip: Pathogenic bacteria can grow in vacuum-sealed food, even when spoilage bacteria are absent. Always check food safety guidelines and monitor for potential risks.

| Practice | Benefit |

|---|---|

| Clean machine after each use | Maintains hygiene and machine longevity |

| Freeze liquids before sealing | Prevents spills and messes |

| Use airtight containers | Limits oxygen exposure |

| Store food in cool, dark places | Extends shelf life |

You protect your food investment by following these best practices. Proper vacuum packaging ensures your food remains safe, fresh, and ready to enjoy.

Vacuum packaging machines help you extend the expiry date of food by creating an oxygen-free environment that slows bacteria and mold. You achieve superior preservation, keeping food fresh up to 3-5 times longer.

You reduce spoilage and enjoy bulk storage.

You maintain flavor, texture, and nutritional value.

You prevent freezer burn and dehydration.

You support health-conscious lifestyles and efficient inventory control.

You make food preservation accessible for both home and business.

Choose advanced solutions from Zhejiang DongFeng Packing Machine Co., Ltd. You enjoy fresher food, less waste, and greater confidence in your preservation process.

Vacuum sealing removes air from packaging. You slow down the growth of bacteria and mold. Food stays fresh longer because oxygen and moisture cannot reach it.

Yes, you can protect electronics, documents, and medical supplies. Vacuum packaging keeps items safe from moisture, dust, and contaminants. You maintain product quality and extend lifespan.

You preserve meats, cheeses, seafood, and vegetables best with vacuum sealing. Dry goods like rice and coffee also last longer. Delicate foods such as herbs and bread stay fresh without damage.

You can safely use vacuum packaging machines at home. Follow food safety guidelines and clean your machine regularly. You keep food fresh and reduce waste with proper use.

You assess your needs based on food type, volume, and space. Select machines with customizable chambers and advanced features. Zhejiang DongFeng Packing Machine Co., Ltd. offers options for both home and commercial use.