Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

You rely on a vacuum packaging machine to keep products fresh and safe for longer periods. This technology removes air and creates a tight seal, which slows down spoilage and protects quality. Many users choose these machines because they can extend the shelf life of food by up to 5 times compared to traditional packaging.

You see less waste and better product quality.

You benefit from advanced features like gas-flushing, precise vacuum control, and strong sealing, all of which affect how long your machine performs at its best.

A vacuum packaging machine is a specialized device that helps you preserve products by removing air from the packaging and sealing it tightly. This process slows down spoilage, maintains freshness, and protects the quality of your goods. You can use these machines in many industries, including food processing, pharmaceuticals, and electronics.

At the core of every machine, several key components work together to deliver reliable results:

| Component | Description |

|---|---|

| Main Frame | Durable stainless steel structure that ensures stability and smooth operation. |

| Control Board | User-friendly interface for adjusting settings and controlling functions. |

| Vacuum Room | Chamber where the packaging process takes place, ensuring a complete cycle. |

| Vacuum Pump | Removes oxygen and internal gases, extending product shelf life. |

| Universal Caster | High-quality wheels that make moving the machine easy and efficient. |

| Sealing Frame | Heated bar that seals the package, locking in freshness. |

| Working Principles | Maintains hygiene by completing air removal and sealing inside the chamber. |

You will find that vacuum packaging machines differ in design and function based on your industry needs.

Machines vary in vacuum strength and sealing methods, which is important for products with high moisture content.

Bag compatibility and operational costs can change depending on the type of bags you use.

User-friendly controls and easy maintenance features help you operate the machine efficiently.

Some models offer extra functions, such as handling liquids or fragile items.

Compact, portable designs are available for smaller businesses or limited spaces.

Recent innovations have brought smart technology integration, such as AI automation and IoT connectivity. These advancements improve efficiency and make your packaging process more reliable. Manufacturers also focus on using environment-conscious materials and enhancing product preservation, so you can meet sustainability goals and maintain product integrity.

Tip: Choosing the right vacuum packaging machine for your business can help you reduce waste, save costs, and deliver higher-quality products to your customers.

You need to select the right packaging materials to maximize the shelf life of your products. High-quality vacuum bags and pouches create a strong barrier against oxygen and moisture. This barrier is essential for keeping food fresh and safe. When you use materials that form airtight seals, you extend the shelf life significantly. Moisture-resistant films help reduce spoilage risk, while temperature control during storage enhances freshness and safety.

| Packaging Material | Effect on Shelf Life |

|---|---|

| Airtight Seals | Extends shelf life significantly |

| Temperature Control | Enhances freshness and safety |

| Moisture Resistance | Reduces spoilage risk |

Vacuum-sealed environments eliminate oxygen, which slows down spoilage. By choosing the right material, you improve the effectiveness of vacuum sealing and gain better control over product preservation. To achieve the best results, you should:

Choose appropriate packaging material.

Ensure airtight seals are achieved.

Maintain optimal temperature and moisture levels.

The features of your vacuum packaging machine play a major role in determining how long your products stay fresh. Look for machines with a high vacuum degree, strong sealing strength, and fast pump speed. For example, a vacuum degree of ≤10Pa removes oxygen thoroughly, which is key to superior preservation. Machines with advanced gas-flushing systems can further extend the shelf life by replacing oxygen with inert gases.

Machine performance depends on vacuum pressure, sealing strength, and pump speed.

Proper packaging preserves cleanliness and prevents recontamination.

Durable inner and outer layers keep out environmental contaminants.

Gas-flushing before sealing maintains clean, dry conditions for sensitive products.

The design and build quality of your vacuum packaging machine affect both its durability and the shelf life of vacuum packaging. Machines made from stainless steel and corrosion-resistant aluminum last longer and perform more reliably. Efficient operation allows you to seal up to 10 packages per minute, which is ideal for busy production lines. Customizable features, such as quick-change molds, let you adapt to different container sizes with ease.

| Feature | Description |

|---|---|

| Durable construction | Stainless steel and corrosion-resistant aluminum for longevity |

| Efficient operation | Handles up to 10 seals per minute |

| Customizable | Quick-change molds for various container sizes |

Fully automatic machines streamline your workflow and reduce the need for manual intervention. When you choose a reliable machine, you minimize downtime and lower maintenance costs, ensuring your packaging operations run smoothly and your products maintain their shelf life.

You can extend the shelf life of meat and seafood dramatically with vacuum packaging. When you store vacuum-sealed meat in the refrigerator, it stays fresh for up to 2-3 weeks. If you freeze vacuum-sealed meat, you can expect it to remain in optimal condition for as long as 12 months. This long shelf life helps you reduce waste and maintain quality, especially in commercial kitchens and food processing facilities.

Vacuum-sealed meat: 2-3 weeks in the refrigerator

Vacuum-sealed meat: up to 12 months in the freezer

Vacuum packaging machines create an oxygen-free environment, which slows bacterial growth and preserves flavor.

You can keep cheese and deli products fresh for extended periods by using vacuum packaging. The shelf life of food such as cheese depends on its type. Hard and semi-soft cheeses last much longer than soft varieties. The following table shows recommended storage times:

| Cheese Type | Storage Time in Vacuum Seal |

|---|---|

| Hard and Semi-Soft | 4-8 months |

| Soft (e.g., Brie) | Shorter lifespan |

Vacuum packaging protects cheese from mold and moisture, helping you deliver consistent quality to your customers.

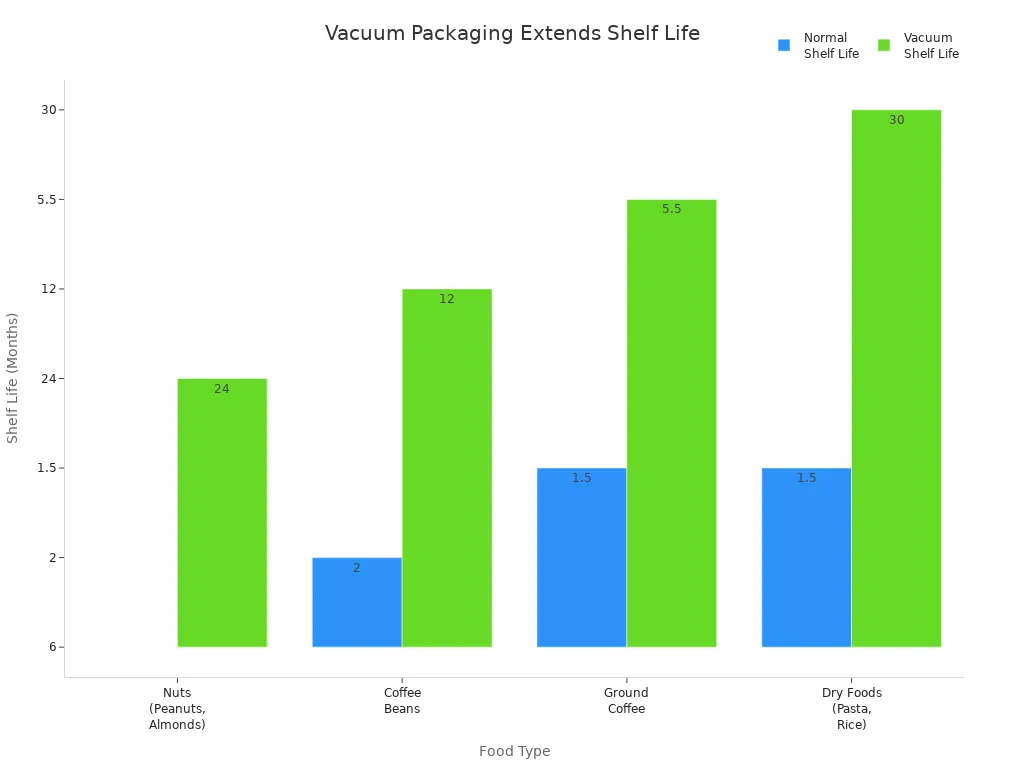

Vacuum packaging offers a significant boost to the shelf life of dry goods. You can see the difference in the table below:

| Food Type | Normal Shelf Life | Vacuum Shelf Life |

|---|---|---|

| Nuts (e.g., Peanuts, Almonds) | 6 Months | 2 Years |

| Coffee Beans | 1-3 Months | 1 Year |

| Ground Coffee | 1-2 Months | 5-6 Months |

| Dry Foods (e.g., Pasta, Rice) | 1-2 Years | 2-3 Years |

You can rely on vacuum packaging to maintain freshness and aroma, especially for coffee and nuts.

Vacuum packaging helps you extend the shelf life of prepared foods. Deli meals and soups stay fresh for 30-45 days when stored at 4°C. This shelf life of vacuum packaging supports food safety and quality in restaurants and catering businesses. You can serve your customers with confidence, knowing your products remain safe and flavorful.

Tip: Using vacuum packaging machines ensures a long shelf life for a wide range of products, helping you meet industry standards and customer expectations.

You will notice clear differences between commercial and household vacuum packaging machines. Commercial models deliver robust performance, supporting high-volume operations in food processing plants, delis, and manufacturing facilities. These machines often carry certifications like UL, ETL, and NSF, which guarantee quality and safety for demanding environments. You benefit from features such as powerful suction, long sealing strips for bulk packaging, and durable Teflon-coated sealing bars. Commercial machines also offer user-friendly controls and automatic modes, making them suitable for continuous use.

Household machines work well for small batches and home kitchens. They extend shelf life by creating an oxygen-free environment, which slows spoilage and preserves freshness. However, commercial machines provide greater efficiency and a broader range of features, resulting in longer shelf life for a wider variety of products. You gain more consistent results and higher productivity with commercial-grade equipment.

Tip: If you manage a business that requires frequent packaging, investing in a commercial vacuum packaging machine ensures durability and superior preservation.

Material compatibility plays a crucial role in vacuum packaging performance. You need machines that handle a variety of packaging materials, including high-barrier films and large bags. Commercial machines often feature adjustable suction settings, allowing you to package different food types and sizes efficiently. The sealing strip’s material, impacts both durability and sealing quality. You can rely on these machines to accommodate bulk items and specialty packaging, which is essential for diverse product lines.

| Feature | Benefit |

|---|---|

| Adjustable suction | Handles various food types |

| Long sealing strip | Accommodates larger bags |

| Durable sealing strip | Ensures long-lasting performance |

You gain a competitive edge by choosing vacuum packaging machines with advanced features. Technological advancements, such as automation and energy efficiency, enhance your operational speed and reduce costs. Automation features like PLCs and touch screens improve productivity and safety, especially in large-scale food processing. Companies that offer customized solutions meet specific industry needs, increasing customer satisfaction.

| Feature | Impact on Competitive Edge |

|---|---|

| Technological Advancements | Boosts efficiency and packaging effectiveness |

| Automation | Cuts labor costs and speeds up operations |

| Energy Efficiency | Reduces expenses and appeals to eco-conscious customers |

| Customized Solutions | Addresses unique industry requirements |

You can increase operational efficiency, ensure consistent packaging, and lower labor costs by selecting machines with these features. Staying ahead in the market means adopting equipment that adapts to your business needs and delivers reliable results every time.

When you invest in a vacuum packaging machine, you want to know how long it will serve your business. The lifespan of your equipment depends on the model, usage, and maintenance. You can expect different results based on the type of machine you choose:

Small budget vacuum sealers or light-duty models usually last about 5 years with regular use.

Industrial-grade vacuum packaging machines often operate for 20 years or more, especially when you follow a proper maintenance schedule.

You can maximize the shelf life of your machine by understanding what causes wear and tear. Several factors can shorten the lifespan of your equipment:

Low vacuum levels may signal a worn pump or leaks in the system.

Poor sealing can result from damaged heating elements or improper bag placement.

Pump overheating often occurs when you run the machine for extended periods without breaks.

Abnormal noise might indicate loose parts or a need for lubrication.

Complete shutdowns usually point to electrical issues or major component failures.

You should perform routine maintenance to ensure a long shelf life for your vacuum packaging machine. Clean the sealing bar, check the vacuum pump oil, and inspect all moving parts regularly. When you address minor issues early, you prevent costly repairs and downtime.

Note: Choosing a high-quality machine and following the manufacturer’s care instructions will help you achieve a long shelf life and reliable performance.

A well-maintained vacuum packaging machine not only extends its own shelf life but also ensures your products stay fresh for longer. You gain peace of mind and better value from your investment.

You need to pay close attention to the moisture content of your products before vacuum packaging. The right moisture level helps preserve quality and color. For example:

Products like chillies with a moisture content of 12% retain color and capsaicin better than those at 10%.

Vacuum packaging controls moisture fluctuations, which prevents microbial growth and oxidation.

Higher moisture levels can slow oxidation, helping products keep their color longer.

When you manage moisture content carefully, you help maintain the shelf life of food and protect its flavor and appearance.

After packaging, you must store your vacuum-sealed products under optimal conditions. Consistent temperature is crucial. You should use an external thermometer to monitor storage areas and keep temperatures within safe limits. To avoid cross-contamination, always separate raw and cooked foods during preparation and sealing. Use different utensils and cutting boards for each type. Recognizing spoilage signs, such as changes in color or odor, ensures you deliver safe and high-quality products.

Tip: Proper storage conditions not only extend freshness but also support food safety in every batch you package.

How you handle vacuum-sealed products after packaging directly affects their shelf life. Oxygen exposure is the main factor that reduces product longevity. Vacuum packaging removes most of the oxygen, which extends shelf life. However, you still need to use proper preservation methods, such as refrigeration, to prevent spoilage. Handle packages gently to avoid breaking the seal or letting air in. Less oxygen means your products stay fresh longer, but only if you maintain the integrity of the packaging and follow safe storage practices.

Selecting the right vacuum packaging machine for your business requires careful consideration. You must match the machine’s capabilities to your products and operational goals. Begin by identifying the types of items you plan to package. Meat, seafood, cheese, dry goods, and prepared foods each have unique requirements. For example, industrial kitchens need machines that handle high volumes and offer features like moisture retention for sous-vide cooking. Smaller businesses may prefer compact models for limited space and lower output.

Your choice depends on several important criteria. Review the table below to guide your decision:

| Criteria | Description |

|---|---|

| Product Type | Match the machine to the specific products you package. |

| Volume | Assess how many items you need to seal each day. |

| Machine Type | Select from chamber, external, double chamber, or belt sealers. |

| Features | Look for pump capacity, seal bar length, and control settings. |

| Brand Reputation | Choose a reliable manufacturer with proven performance. |

| Operational Efficiency | Evaluate ease of use and maintenance needs. |

| Cost | Balance initial investment with long-term savings. |

| Compliance | Ensure the machine meets industry standards. |

| Scalability | Pick a model that can grow with your business. |

You should also consider your intended application. Chamber units suit larger packages and industrial use. Non-chamber machines, such as nozzle or edge sealers, work well in residential or small-scale settings. Follow these steps to simplify your selection process:

Identify your main packaging goals, such as preventing spoilage or oxidation.

Research available machine types and features.

Choose a model that fits your product volume and future growth plans.

Tip: A well-chosen vacuum packaging machine improves efficiency, reduces waste, and supports your business as it expands.

You can rely on a vacuum packaging machine to extend the shelf life of meats, deli products, dry goods, and prepared foods. Regular maintenance, such as checking fluid levels and cleaning nozzles, keeps your equipment running smoothly and prolongs its service life. When you invest in a premium machine, you create a low-oxygen environment that preserves freshness and reduces food waste. Choosing the right model and following a maintenance schedule ensures you get the best shelf life and value for your business.

You should perform basic maintenance, such as cleaning the sealing bar and checking the vacuum pump oil, every 500 hours of operation. Regular maintenance helps you prevent breakdowns and extend your machine’s lifespan.

You need to use bags designed for vacuum sealing. High-barrier or multi-layer bags work best. These bags help you achieve a strong seal and maximize shelf life for your products.

Single chamber machines suit small batches and limited space. Dual chamber machines increase productivity and reduce cycle time. You can choose based on your production needs and available workspace.

Vacuum packaging preserves the natural taste and texture of food. You keep flavors locked in and prevent freezer burn or dehydration. This method helps you deliver consistent quality to your customers.

Watch for signs like weak vacuum pressure, poor sealing, or unusual noises. If you notice these issues, schedule a professional inspection. Prompt repairs help you avoid downtime and protect your products.