loading

| Availability: | |

|---|---|

| Quantity: | |

FM-5540

DFPACK

Boxes

Cartons

Shrink Packaging

Medium

Advantage

Stainless Steel Fan: Equipped with a stainless steel fan for increased longevity.

Spray Coating: The entire machine features spray coating for enhanced rust and corrosion resistance, and a more attractive appearance.

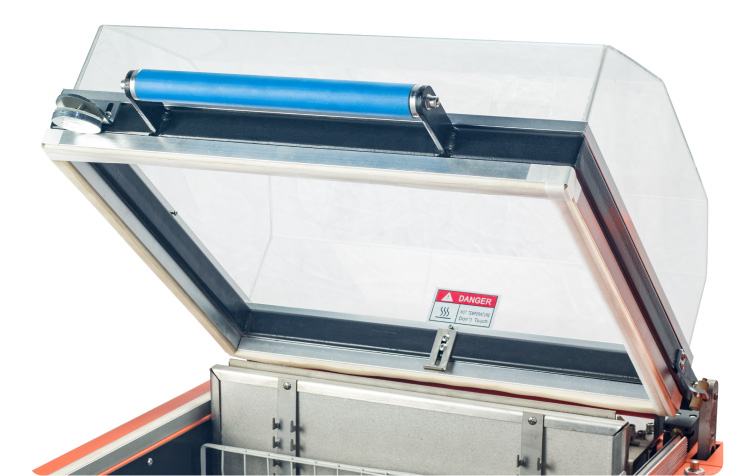

PVC Cover: The machine's cover is made of transparent PVC, allowing easy observation of the working chamber.

Mobility: Features casters on the bottom for easy movement.

High-Power Heating Element: Equipped with a high-power heating tube to significantly reduce shrinkage time.

Heat Cutting Function: Includes a heat cutting feature for a more aesthetically pleasing seal.

Roller Pins: The rollers are equipped with pins to prevent air bubbles in the shrink film.

Model | FM-5540 |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 3kw |

| Max Packing Size | 21.7 x 15.7 x 7.9 inch 550x400x200mm |

| Shink Time | 1-4p/min |

| Dimension | 53.7 x 27.2 x 43.3 inch 1365x690x1100mm |

| Weight | 286.6 lb 130kgs |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

CERTIFICATE

Global Distributor Program | 12+ International Exhibitions Annually

With 36+ years of vacuum packaging expertise, we showcase CE-certified, self-designed machinery at premier exhibitions including CANTON FAIR, INTERPACK, PROPAK, and SWOP.

Highlights

Global Support:Annual production capacity exceeding 2,000,000 units. Exported to 100+ countries.

Tailored Solutions:Our team delivers professional vacuum packaging solutions leveraging extensive experience, backed by reliable after-sales service.

Clients as Partners:We treat every customer as a valued partner, prioritizing their needs and concerns to ensure tangible benefits.

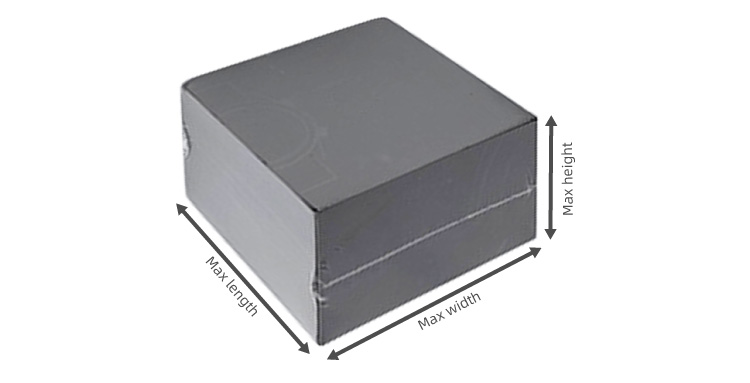

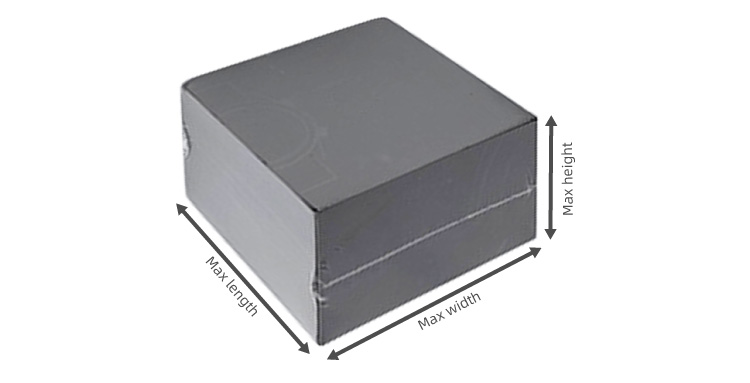

MAXIMUM PACKAGE SIZE

| max length: | 21.7 inch(550mm) |

| max width: | 15.7 inch(400mm) |

| max height: | 7.9 inch(200mm) |

LARGE METAL BLADES

The wind blades make the shrinkage furnace form a good wind circulation and heat evenly

Metal blades are not afraid of high temperature and high load operation

UNLIKE MANUAL THERMAL SHRINKAGE

HAVE A SIGNIFICANT ADVANTAGE

EFFICIENCY

It integrates sealing, cutting and thermal shrinkage, making operation simpler and more efficient

EFFECT

Uniform and beautiful packaging

Enhance product value

OPERATION

Intelligent temperature control

Uniform heat shrinkage, efficient and fast

MOVABLE SEPARATOR PLATE AND LOADING WHEEL

It can be freely adjusted according to the size of the product package

Wide adjustment range to meet different needs

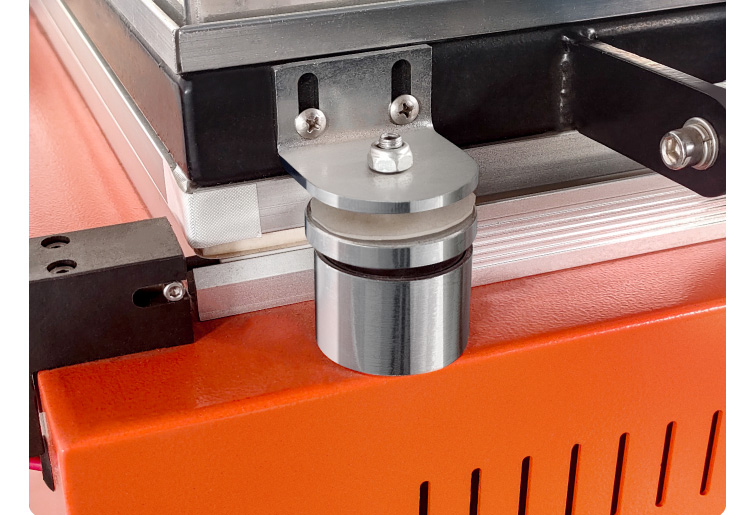

ADJUSTABLE SUPPORT HEIGHT

The height of the bracket can be adjusted according to the height of the product, so that the film size and packaging match

SIMPLE CONTROL PANEL

Easy to set up and operate

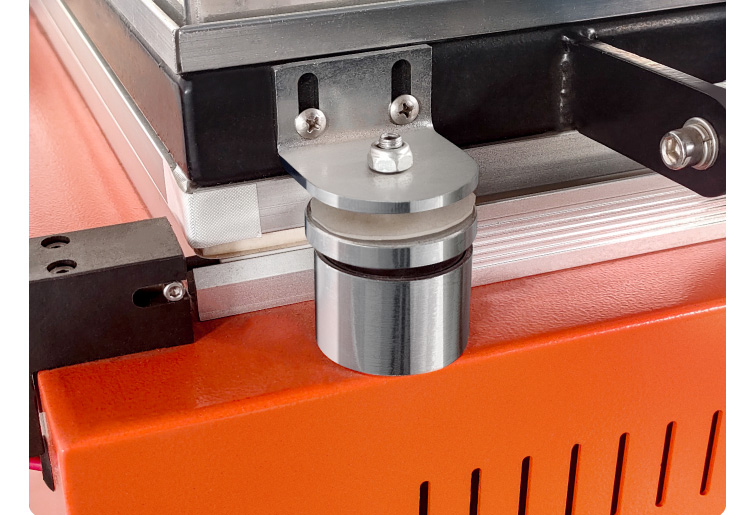

ELECTROMAGNET

A glass cover can be added to firmly absorb the contraction chamber to achieve a closed effect

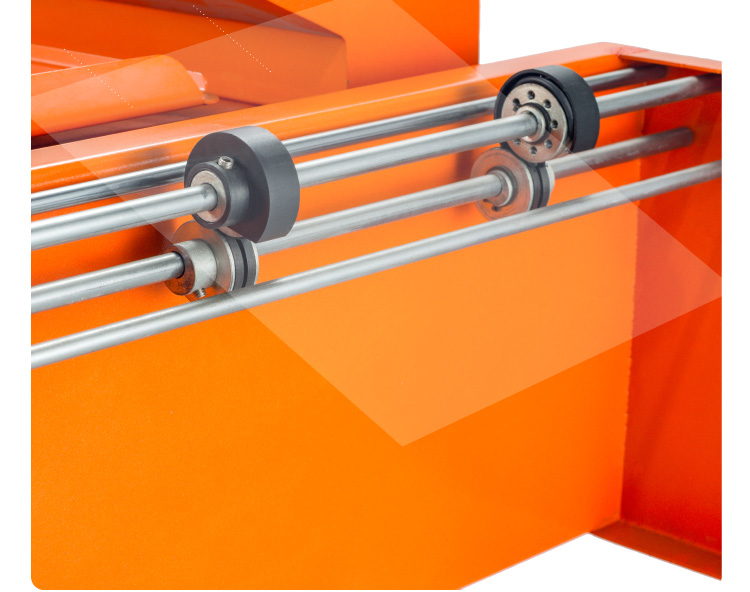

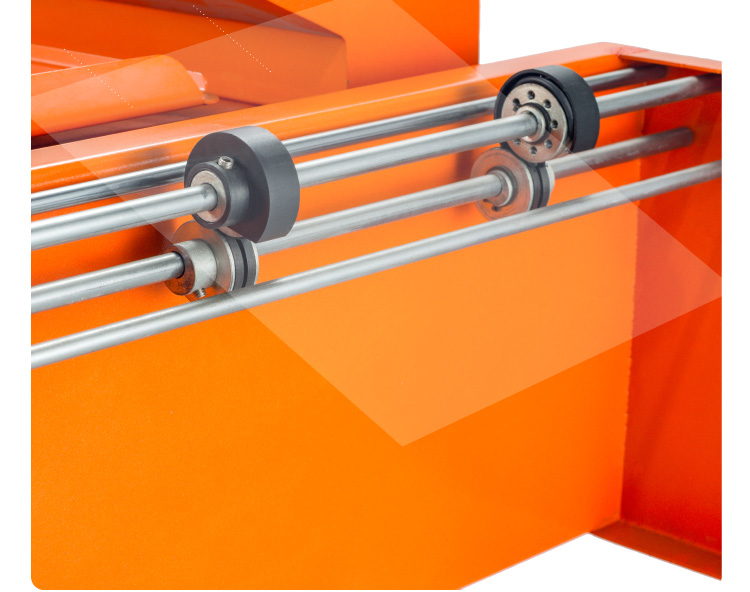

NEEDLE WHEEL

In the process of film shrinkage, the air is discharged in time to make the product shrink better

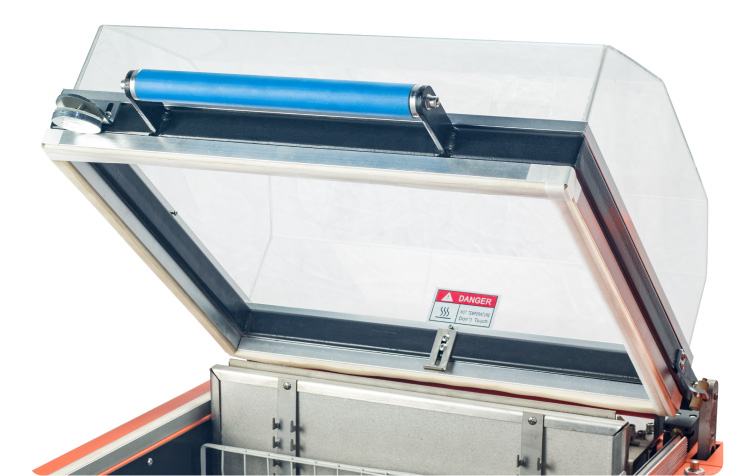

TRANSPARENT ORGANIC LID

High temperature resistant plexiglass cover, the contraction process at a glance

The packaging effect can be adjusted in time

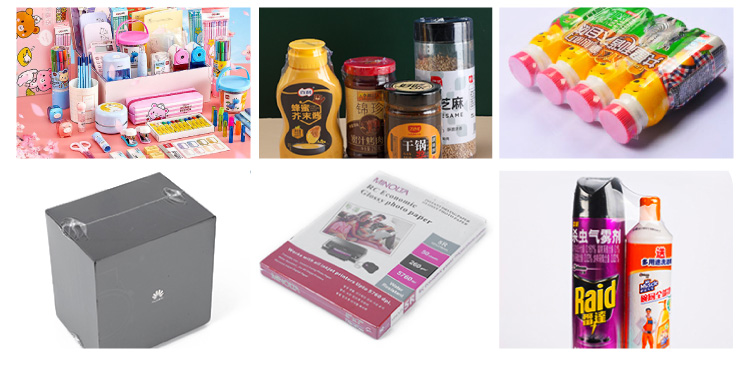

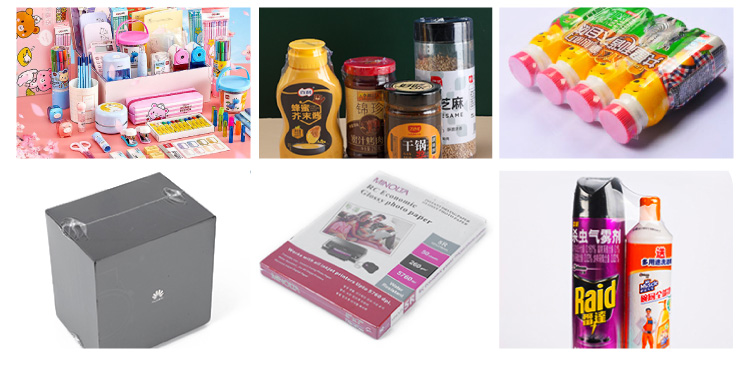

APPLICATION

PACKAGING & SHIPPING

Your machine will be delivered by sea, air or express according to your needs.Before packaging, the goods are first wrapped with protective film to prevent scratches and corrosion, and then placed in wooden boxes for shipment.

OUT OF THE BOX

No installation required

So far, the factory covers an area of 26,800 square meters and has more than 300 workers, among whom there are 40 engineering and technical personnel. As a national high-tech enterprise, we have a mature management system covering R&D, production, sales, quality inspection and after-sales service. After 36 years of efforts, our company's annual production capacity is currently approximately 2,000,000 sets, and our products are exported to over 100 countries.

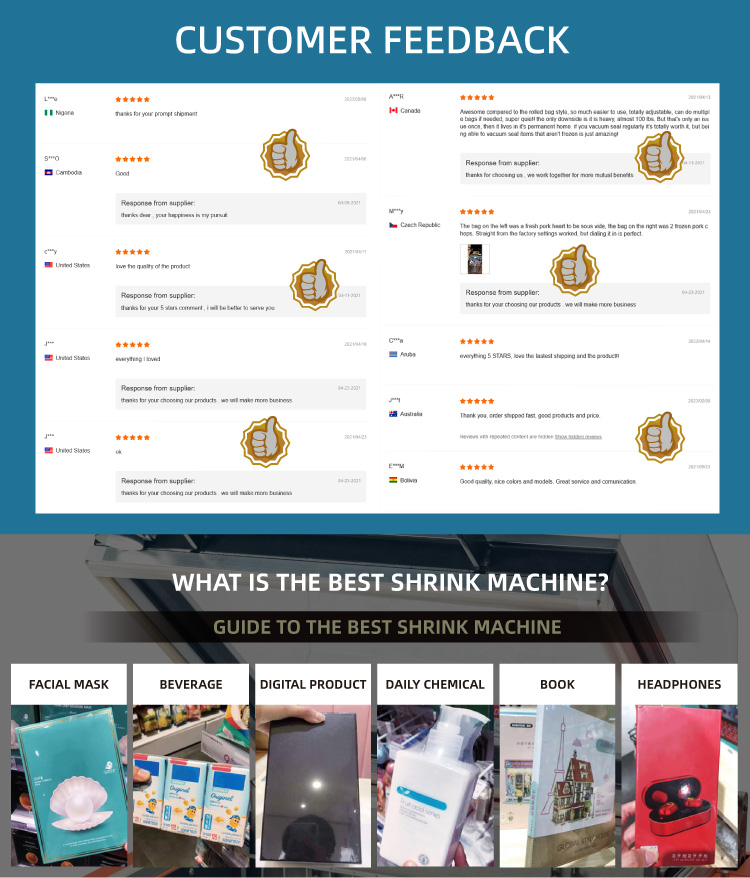

FAQ

Advantage

Stainless Steel Fan: Equipped with a stainless steel fan for increased longevity.

Spray Coating: The entire machine features spray coating for enhanced rust and corrosion resistance, and a more attractive appearance.

PVC Cover: The machine's cover is made of transparent PVC, allowing easy observation of the working chamber.

Mobility: Features casters on the bottom for easy movement.

High-Power Heating Element: Equipped with a high-power heating tube to significantly reduce shrinkage time.

Heat Cutting Function: Includes a heat cutting feature for a more aesthetically pleasing seal.

Roller Pins: The rollers are equipped with pins to prevent air bubbles in the shrink film.

Model | FM-5540 |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 3kw |

| Max Packing Size | 21.7 x 15.7 x 7.9 inch 550x400x200mm |

| Shink Time | 1-4p/min |

| Dimension | 53.7 x 27.2 x 43.3 inch 1365x690x1100mm |

| Weight | 286.6 lb 130kgs |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

CERTIFICATE

Global Distributor Program | 12+ International Exhibitions Annually

With 36+ years of vacuum packaging expertise, we showcase CE-certified, self-designed machinery at premier exhibitions including CANTON FAIR, INTERPACK, PROPAK, and SWOP.

Highlights

Global Support:Annual production capacity exceeding 2,000,000 units. Exported to 100+ countries.

Tailored Solutions:Our team delivers professional vacuum packaging solutions leveraging extensive experience, backed by reliable after-sales service.

Clients as Partners:We treat every customer as a valued partner, prioritizing their needs and concerns to ensure tangible benefits.

MAXIMUM PACKAGE SIZE

| max length: | 21.7 inch(550mm) |

| max width: | 15.7 inch(400mm) |

| max height: | 7.9 inch(200mm) |

LARGE METAL BLADES

The wind blades make the shrinkage furnace form a good wind circulation and heat evenly

Metal blades are not afraid of high temperature and high load operation

UNLIKE MANUAL THERMAL SHRINKAGE

HAVE A SIGNIFICANT ADVANTAGE

EFFICIENCY

It integrates sealing, cutting and thermal shrinkage, making operation simpler and more efficient

EFFECT

Uniform and beautiful packaging

Enhance product value

OPERATION

Intelligent temperature control

Uniform heat shrinkage, efficient and fast

MOVABLE SEPARATOR PLATE AND LOADING WHEEL

It can be freely adjusted according to the size of the product package

Wide adjustment range to meet different needs

ADJUSTABLE SUPPORT HEIGHT

The height of the bracket can be adjusted according to the height of the product, so that the film size and packaging match

SIMPLE CONTROL PANEL

Easy to set up and operate

ELECTROMAGNET

A glass cover can be added to firmly absorb the contraction chamber to achieve a closed effect

NEEDLE WHEEL

In the process of film shrinkage, the air is discharged in time to make the product shrink better

TRANSPARENT ORGANIC LID

High temperature resistant plexiglass cover, the contraction process at a glance

The packaging effect can be adjusted in time

APPLICATION

PACKAGING & SHIPPING

Your machine will be delivered by sea, air or express according to your needs.Before packaging, the goods are first wrapped with protective film to prevent scratches and corrosion, and then placed in wooden boxes for shipment.

OUT OF THE BOX

No installation required

So far, the factory covers an area of 26,800 square meters and has more than 300 workers, among whom there are 40 engineering and technical personnel. As a national high-tech enterprise, we have a mature management system covering R&D, production, sales, quality inspection and after-sales service. After 36 years of efforts, our company's annual production capacity is currently approximately 2,000,000 sets, and our products are exported to over 100 countries.

FAQ