loading

DFJ-130P

DFPACK

Liquids

Pouch

Filling Packaging

High

Advanced Measurement Accuracy

Incorporates a high-precision microcomputer control system for accurate portioning of liquid or semi-liquid products, reducing waste and maintaining consistency.

Fully Automated Filling Process

Automates the process of loading sauces into pre-formed packaging, enhancing efficiency and reducing manual intervention.

Smooth Sealing and Trimming

Integrates cutting-edge sealing technology that ensures airtight sealing and clean edge trimming for a polished finish.

Customizable Cutting Length

Equipped with adjustable settings to cut packaging material precisely to desired lengths, catering to diverse product requirements.

The Sauce Packaging Machine is suitable for:

Condiment Packaging: The Sauces Packing Machine Perfect for ketchup, mustard, mayonnaise, and soy sauce.

Food Processing Plants: Packaging chili paste, curry sauces, and other semi-liquid food products.

Retail and E-Commerce: Preparing single-serve or bulk sauce packets for online and supermarket distribution.

Commercial Catering: High-volume packaging for food service providers and restaurant supply chains.

FAQ

Q:Do you provide samples? Is it free or paid?

A:Answer: For the first cooperation, we will charge a sample fee. However, when you place an order, we will refund the sample fee. The express delivery cost of the samples will be paid by the buyer.

Q:How to handle the malfunction?

A:We prioritize fault prevention through a strict quality management system to ensure that the product failure rate is below 0.2%. In case of any malfunction, we offer 24-hour online investigation of the cause of the accident. If replacement parts are needed, we will ensure prompt delivery to minimize downtime and your losses. For large order customers, we will have accessory solutions for the machines.

| Model | DFJ-130P |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 0.9kw |

| Diameter of packaging film | Φ7.9 inch Φ200mm |

| Weight | 77.2 lb 35kgs |

| Certification | CE ISO |

ONE STEP PACKAGING

DFJ-130P with jet printing paste machine

It is widely used in many materials

AUTOMATIC MEASUREMENT

Adopting intelligent microcomputer control technology for precise and automatic measurement.

AUTOMATIC FILLING

Automatically loading the paste liquid into the packaging bag

AUTOMATIC CUTTING

After packaging, the machine will accurately cut according to the set length.

AUTOMATIC ENCAPSULATION

After cutting, the machine automatically seals and trims the edges achieving good results.

BUILT-IN CODING MODULE

Enable the inkjet function to print custom text content

PRODUCT PACKAGING EFFECT DRAWING

Three-side sealing bag, smooth packaging, stable operation

Front and back effects

THE LENGTH CAN BE ADJUSTED

Adjust the different Settings of the machine according to the packaging specifications and bag weight.

BAG SIZE:

Length 2.0 - 7.9 inch(50 - 200MM)

width 2.6 inch(65MM)

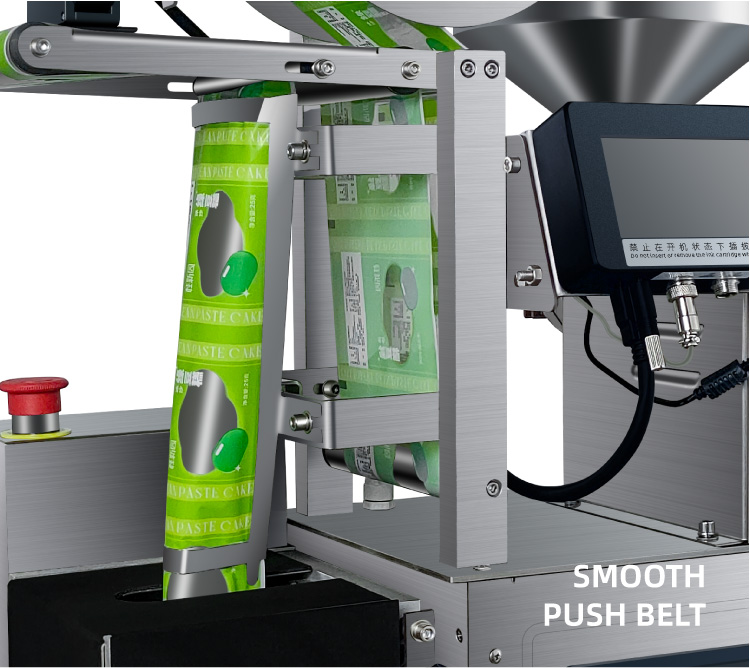

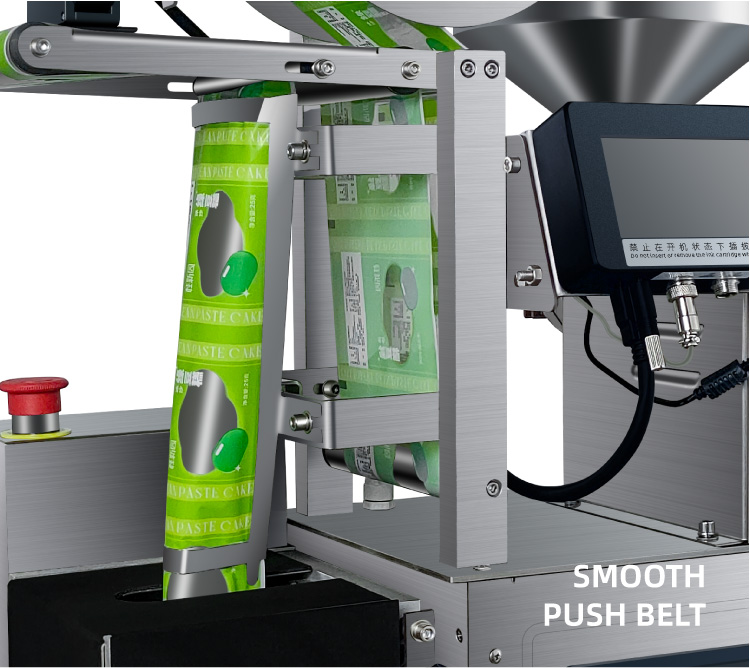

SMOOTH FILM DELIVERY STRUCTURE

Stainless steel curved bag molding machine is used to fold the bag in half neatly, and the finished product is more beautiful.

STAINLESS STEEL CONSTRUCTION

Stainless steel frame, beautiful appearance, wet and corrosion resistancelong service life

PRINT CONTROL SYSTEM

Independent print control system to customize the print content

FOOD GRADE 304 STAINLESS STEEL

It is corrosion-resistant, sturdy and durable, ensuring stable operation of the machine in various environments

STEPPER MOTOR

Bidirectional pull film structure,not easy to pull loss, high accuracy,low electromagnetic loss, and high conversion rate.

PACKAGING & SHIPPING

MACHINE NEEDS TO BE INSTALLED

Requires installation to use

Advanced Measurement Accuracy

Incorporates a high-precision microcomputer control system for accurate portioning of liquid or semi-liquid products, reducing waste and maintaining consistency.

Fully Automated Filling Process

Automates the process of loading sauces into pre-formed packaging, enhancing efficiency and reducing manual intervention.

Smooth Sealing and Trimming

Integrates cutting-edge sealing technology that ensures airtight sealing and clean edge trimming for a polished finish.

Customizable Cutting Length

Equipped with adjustable settings to cut packaging material precisely to desired lengths, catering to diverse product requirements.

The Sauce Packaging Machine is suitable for:

Condiment Packaging: The Sauces Packing Machine Perfect for ketchup, mustard, mayonnaise, and soy sauce.

Food Processing Plants: Packaging chili paste, curry sauces, and other semi-liquid food products.

Retail and E-Commerce: Preparing single-serve or bulk sauce packets for online and supermarket distribution.

Commercial Catering: High-volume packaging for food service providers and restaurant supply chains.

FAQ

Q:Do you provide samples? Is it free or paid?

A:Answer: For the first cooperation, we will charge a sample fee. However, when you place an order, we will refund the sample fee. The express delivery cost of the samples will be paid by the buyer.

Q:How to handle the malfunction?

A:We prioritize fault prevention through a strict quality management system to ensure that the product failure rate is below 0.2%. In case of any malfunction, we offer 24-hour online investigation of the cause of the accident. If replacement parts are needed, we will ensure prompt delivery to minimize downtime and your losses. For large order customers, we will have accessory solutions for the machines.

| Model | DFJ-130P |

| Voltage | 110/220V 50-60Hz |

| Pump Power | 0.9kw |

| Diameter of packaging film | Φ7.9 inch Φ200mm |

| Weight | 77.2 lb 35kgs |

| Certification | CE ISO |

ONE STEP PACKAGING

DFJ-130P with jet printing paste machine

It is widely used in many materials

AUTOMATIC MEASUREMENT

Adopting intelligent microcomputer control technology for precise and automatic measurement.

AUTOMATIC FILLING

Automatically loading the paste liquid into the packaging bag

AUTOMATIC CUTTING

After packaging, the machine will accurately cut according to the set length.

AUTOMATIC ENCAPSULATION

After cutting, the machine automatically seals and trims the edges achieving good results.

BUILT-IN CODING MODULE

Enable the inkjet function to print custom text content

PRODUCT PACKAGING EFFECT DRAWING

Three-side sealing bag, smooth packaging, stable operation

Front and back effects

THE LENGTH CAN BE ADJUSTED

Adjust the different Settings of the machine according to the packaging specifications and bag weight.

BAG SIZE:

Length 2.0 - 7.9 inch(50 - 200MM)

width 2.6 inch(65MM)

SMOOTH FILM DELIVERY STRUCTURE

Stainless steel curved bag molding machine is used to fold the bag in half neatly, and the finished product is more beautiful.

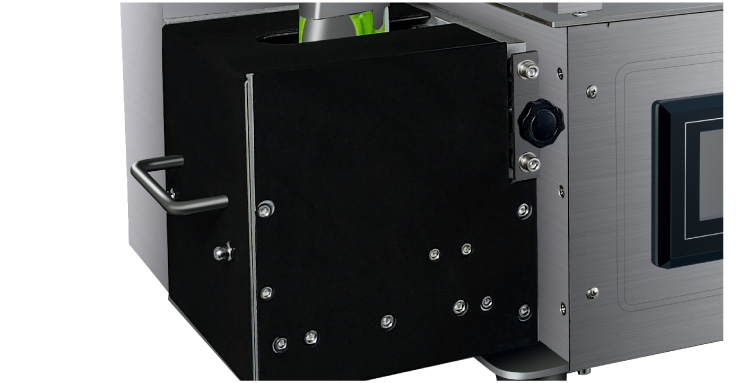

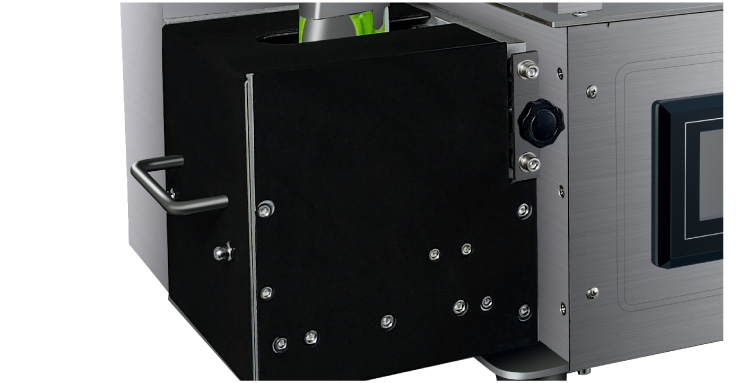

STAINLESS STEEL CONSTRUCTION

Stainless steel frame, beautiful appearance, wet and corrosion resistancelong service life

PRINT CONTROL SYSTEM

Independent print control system to customize the print content

FOOD GRADE 304 STAINLESS STEEL

It is corrosion-resistant, sturdy and durable, ensuring stable operation of the machine in various environments

STEPPER MOTOR

Bidirectional pull film structure,not easy to pull loss, high accuracy,low electromagnetic loss, and high conversion rate.

PACKAGING & SHIPPING

MACHINE NEEDS TO BE INSTALLED

Requires installation to use