loading

| Availability: | |

|---|---|

| Quantity: | |

DF-370

DFPACK

Meat, Seafood, Cooked Food, Fruits and Vegetables, Liquids

Food Plastic Trays

Atmosphere Packaging

Low

Technical Highlights

Intelligent positioning pressure seal: the tray rotates to the working area to automatically trigger the pressure, a single cycle only a few seconds, support continuous box placement uninterrupted operation, efficiency is 50% higher than the traditional model.

Industrial precision edge sealing : to ensure that the four corners of the box body uniform force, suitable for PP/PS/PET food grade lunch box, sealing strength up to 8N/15mm tear resistance standard

Surgical grade film cutting process : built-in arc cutting knife, 0.2mm ultra-thin slit to complete sealing and film excising simultaneously, smooth incision without burrs.

Scene Enable

Take-out booth: the square box is continuously sealed to cope with the meal pressure during the afternoon and evening peak.

Cooked food workshop: soup package, rotating tray fit square box body.

Fresh pre-storage: lock fresh + moisture-proof sealing film.

Support a variety of box depth, compatible with kitchen/market and other scenarios, through CE certification, redefine efficient packaging productivity.

| Model | DF-370 |

| Voltage | 110/220/380V 50-60Hz |

| Pump Power | 0.9kw |

| Efficiency | 6~7times/min |

| Dimensions | 17.7 × 28.3 × 29.5 inch (450×720×750mm) |

| Weight | 172.0 lb(≈78kgs) |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

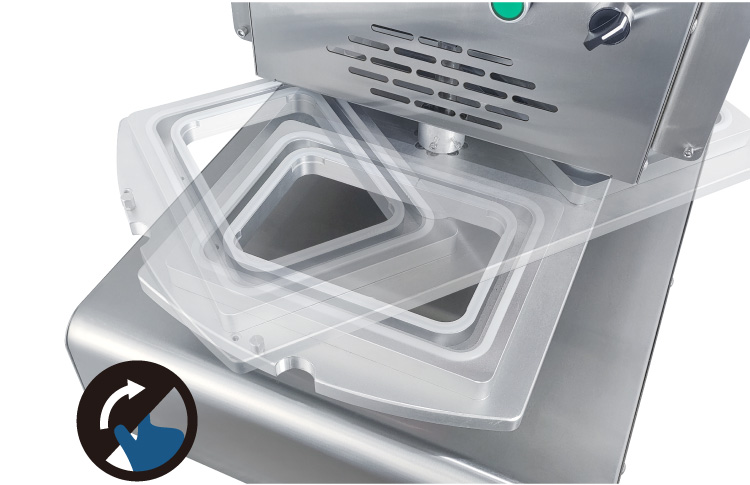

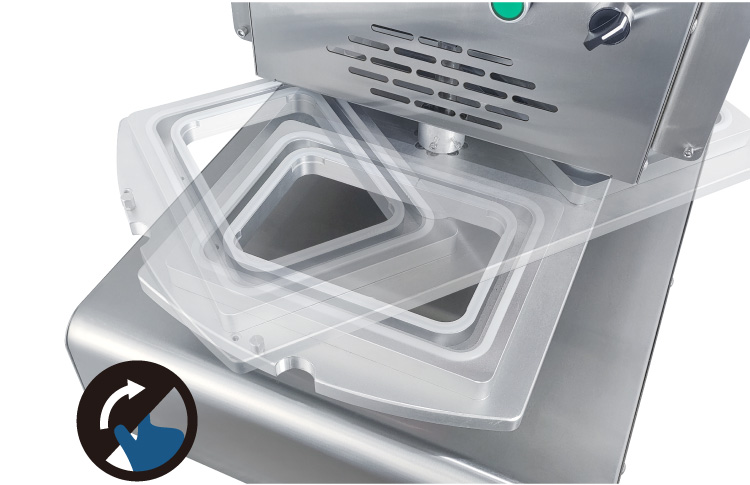

DEFAULT TRAY SIZE

Mold support customization

WORKING PRINCIPLE

The air transfer machine is used to extract air from the packaging to create a vacuum environment.

Fill with a specific proportion of protective gas mixture.

Sealed packaging to ensure that the internal environment will not be polluted by outside air.

2 STATIONS WORK IN ROTATION

efficient use of packaging gap time improve production efficiency

The machine needs to rotate the turntable manually

Get the machine in for the next job

COMPLETE IN ONE GO

Vacuum, aeration, sealing and film cutting are completed at one time

STAINLESS STEEL BODY

Stainless steel frame, beautiful appearance, wet and corrosion resistance,

easy to clean,Not easily deformed,long service life

SUPPORT MOLD CUSTOMIZATION

According to the needs, customize the corresponding model

SIMPLE CONTROL PANEL

Easy to operate, simple interface, easy to use

FILM SPOOL

Release and recycle the film synchronously, the film is more flat, keep clean

PRESET ROTATION ANGLE

When manually rotating the table, it can just stop in the pre-set position

APPLICATION

OUT OF THE BOX

No installation required

Technical Highlights

Intelligent positioning pressure seal: the tray rotates to the working area to automatically trigger the pressure, a single cycle only a few seconds, support continuous box placement uninterrupted operation, efficiency is 50% higher than the traditional model.

Industrial precision edge sealing : to ensure that the four corners of the box body uniform force, suitable for PP/PS/PET food grade lunch box, sealing strength up to 8N/15mm tear resistance standard

Surgical grade film cutting process : built-in arc cutting knife, 0.2mm ultra-thin slit to complete sealing and film excising simultaneously, smooth incision without burrs.

Scene Enable

Take-out booth: the square box is continuously sealed to cope with the meal pressure during the afternoon and evening peak.

Cooked food workshop: soup package, rotating tray fit square box body.

Fresh pre-storage: lock fresh + moisture-proof sealing film.

Support a variety of box depth, compatible with kitchen/market and other scenarios, through CE certification, redefine efficient packaging productivity.

| Model | DF-370 |

| Voltage | 110/220/380V 50-60Hz |

| Pump Power | 0.9kw |

| Efficiency | 6~7times/min |

| Dimensions | 17.7 × 28.3 × 29.5 inch (450×720×750mm) |

| Weight | 172.0 lb(≈78kgs) |

| Certification | CE ISO |

Dongfeng Packing:China's Top-Tier Brand with 36 Years of Excellence

Since our factory's establishment in 1989, we have dedicated decades to specializing in the vacuum packaging industry. Recognized as a National High-Tech Enterprise by the Chinese government and holding 100+ patents, we serve as a certified supplier to distinguished clients including:

·Chinese Government Supply Units

·Bank of China

·Sam's Club

·and other global entities

DEFAULT TRAY SIZE

Mold support customization

WORKING PRINCIPLE

The air transfer machine is used to extract air from the packaging to create a vacuum environment.

Fill with a specific proportion of protective gas mixture.

Sealed packaging to ensure that the internal environment will not be polluted by outside air.

2 STATIONS WORK IN ROTATION

efficient use of packaging gap time improve production efficiency

The machine needs to rotate the turntable manually

Get the machine in for the next job

COMPLETE IN ONE GO

Vacuum, aeration, sealing and film cutting are completed at one time

STAINLESS STEEL BODY

Stainless steel frame, beautiful appearance, wet and corrosion resistance,

easy to clean,Not easily deformed,long service life

SUPPORT MOLD CUSTOMIZATION

According to the needs, customize the corresponding model

SIMPLE CONTROL PANEL

Easy to operate, simple interface, easy to use

FILM SPOOL

Release and recycle the film synchronously, the film is more flat, keep clean

PRESET ROTATION ANGLE

When manually rotating the table, it can just stop in the pre-set position

APPLICATION

OUT OF THE BOX

No installation required