loading

| Availability: | |

|---|---|

| Quantity: | |

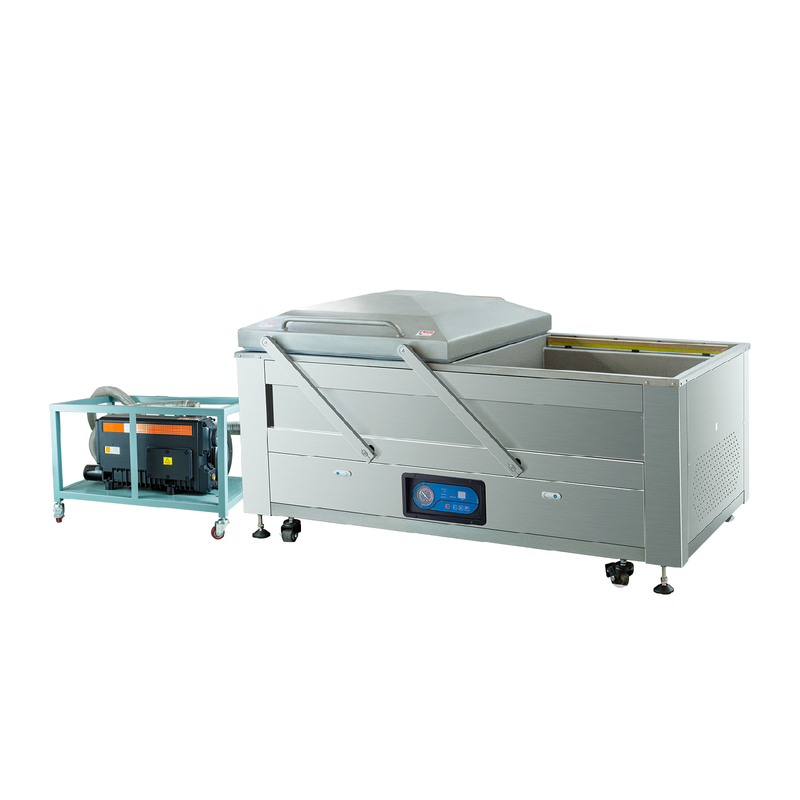

DZQ-900/2SA

DFBZ

Meat, Seafood, Cooked Food, Fruits and Vegetables, Granules, Liquids, Powders, Medical Equipment, Hardware

Pouch

Vacuum Packaging

High

The machine is made of 96% stainless steel.

It features patented technology, allowing the easy transfer of the 900-type vacuum cover to another chamber.

The machine can be customized with a vacuum chamber depth of up to 350mm.

It can be equipped with vacuum pumps ranging from 100 to 400m³; larger m³ indicates greater suction power.

It uses a concave vacuum chamber to effectively address product space issues.

The machine is controlled by a PCB board.

It offers an optional gas flushing feature.

It has a plug-in sealing strip for easier replacement of heating wires.

It includes a separate electrical box for quicker maintenance and inspection.

| Model | DZQ-900/2SA |

| Power supply | 3PH220V/380V 50/60Hz |

| Power | 4000W |

| Chamber size | 1000*850*350mm |

| Seal bar length | 900mm(X4) |

| Seal width | 10mm |

| Pump capacity | 200m³(X1)/Option |

| Dimension | 2145*1100*1155mm |

| Weigth | ≈550kgs |

| Certification | CE ISO |

FAQ:

Q: What is the main function of a large double-chamber vacuum machine?

A: A large double-chamber vacuum machine is used for vacuum sealing large quantities or oversized items. It features two separate sealing chambers that can process multiple packages simultaneously, making it suitable for high-capacity applications in food processing, medical equipment, and industrial products.

Q: How do I set the vacuum level and sealing time on a large double-chamber vacuum machine?

A: The vacuum level and sealing time are typically adjusted using controls on the machine's panel or touchscreen. Set the parameters according to the packaging materials and product requirements. For specific instructions, refer to the user manual.

Q: What types of packaging materials are suitable for a large double-chamber vacuum machine?

A: A large double-chamber vacuum machine is suitable for various packaging materials, including plastic bags, aluminum foil bags, and composite films. Choose materials that ensure optimal vacuum and sealing performance.

The machine is made of 96% stainless steel.

It features patented technology, allowing the easy transfer of the 900-type vacuum cover to another chamber.

The machine can be customized with a vacuum chamber depth of up to 350mm.

It can be equipped with vacuum pumps ranging from 100 to 400m³; larger m³ indicates greater suction power.

It uses a concave vacuum chamber to effectively address product space issues.

The machine is controlled by a PCB board.

It offers an optional gas flushing feature.

It has a plug-in sealing strip for easier replacement of heating wires.

It includes a separate electrical box for quicker maintenance and inspection.

| Model | DZQ-900/2SA |

| Power supply | 3PH220V/380V 50/60Hz |

| Power | 4000W |

| Chamber size | 1000*850*350mm |

| Seal bar length | 900mm(X4) |

| Seal width | 10mm |

| Pump capacity | 200m³(X1)/Option |

| Dimension | 2145*1100*1155mm |

| Weigth | ≈550kgs |

| Certification | CE ISO |

FAQ:

Q: What is the main function of a large double-chamber vacuum machine?

A: A large double-chamber vacuum machine is used for vacuum sealing large quantities or oversized items. It features two separate sealing chambers that can process multiple packages simultaneously, making it suitable for high-capacity applications in food processing, medical equipment, and industrial products.

Q: How do I set the vacuum level and sealing time on a large double-chamber vacuum machine?

A: The vacuum level and sealing time are typically adjusted using controls on the machine's panel or touchscreen. Set the parameters according to the packaging materials and product requirements. For specific instructions, refer to the user manual.

Q: What types of packaging materials are suitable for a large double-chamber vacuum machine?

A: A large double-chamber vacuum machine is suitable for various packaging materials, including plastic bags, aluminum foil bags, and composite films. Choose materials that ensure optimal vacuum and sealing performance.